Creating detailed and accurate jewelry designs can be challenging without the right tools. For jewelers seeking precision and efficiency, choosing the best 3d wax printer for jewelry is a key step toward improving craftsmanship and speeding up production. This type of printer is designed specifically for making wax models that serve as the basis for casting intricate jewelry pieces.

Whether you are a professional jeweler or a small business owner, a reliable 3D wax printer can save time and reduce material waste compared to traditional methods. In this review, we will explore some of the leading options available, highlighting their features, ease of use, and accuracy.

By the end, you’ll have a clearer idea of which printer fits your specific needs and workflow.

| Image | Name | Our Rating | Price |

|---|---|---|---|

|

3DMaterials SuperCast 8K 3D Printer Resi...

|

|

|

|

3DMaterials SuperCast 8K 3D Printer Resi...

|

|

|

|

Siraya Tech Cast 3D Printer Resin Easy t...

|

|

Discover Top Solutions Revolutionizing Jewelry Design with Precision and Detail

| Image | Product | Price |

|---|---|---|

Our Top Picks 1  | SuperCast 8K 3D Printer Resin Wax Filled for Ultrafine Filigree, | Check Price |

Our Top Picks 2  | SuperCast 8K 3D Printer Resin Wax Filled for Ultrafine Filigree, | Check Price |

Our Top Picks 3  | Siraya Tech Cast 3D Printer Resin Easy to Print Use | Check Price |

1. SuperCast 8K 3D Printer Resin Wax Filled for Ultrafine Filigree,

Discover precision and strength combined with the SuperCast 8K 3D Printer Resin Wax Filled for Ultrafine Filigree. Crafted for highly detailed jewelry designs, this resin enables intricate creations with exceptional clarity. It caters to professionals seeking flawless fine-detail printing without compromise.

It caters to professionals seeking flawless fine-detail printing without compromise.

Ideal for jewelry makers and designers, the resin supports ultrafine filigree work thanks to its unique wax-filled composition. This material ensures strong, stiff prints that maintain delicate detail during the printing process. The absence of a required post-curing step simplifies workflows and reduces the risk of incomplete burning during casting procedures.

The absence of a required post-curing step simplifies workflows and reduces the risk of incomplete burning during casting procedures.

The resin offers an extremely low viscosity that promotes high-resolution 8K printing with an astounding 22μm layer accuracy. This facilitates fast and precise output, making it suitable for complex models with fine features.

Its wax content allows it to burn out cleanly at lower temperatures, leaving no residue or ash behind. This enhances casting quality by preventing contamination and defects.

Compatibility with all regular and mono LCD 3D printers adds flexibility across various hardware setups. The resin’s unique photosensitization technology guarantees reliable curing irrespective of the printer type.

Weighing just 2 pounds and housed in compact packaging, it fits well in any workspace. Customers have reported successful resin burnout using a simple jewelry torch, eliminating the need for expensive ovens or kilns.

The build quality supports tough, precise jewelry patterns with excellent stiffness to avoid deformation. With its blend of performance, ease of use, and industry-specific features, this resin stands out among wax resins intended for jewelry manufacturing.

It suits artisans who demand fine detail combined with dependable burnout characteristics, enhancing the casting process.

Pros

- Wax-filled resin ensures strong, stiff prints ideal for delicate filigree.

- Complete burnout at low temperatures prevents ash residue.

- 8K resolution with 22μm precision supports ultra-fine detail printing.

Cons

- Requires careful handling to avoid incomplete burns if post-curing is used.

The SuperCast 8K 3D Printer Resin Wax Filled delivers unmatched precision and clean burnout for jewelry production. Its unique formulation bridges the gap between delicate design requirements and efficient casting preparation, making it a trusted choice for professional jewelers aiming for perfection.

2. SuperCast 8K 3D Printer Resin Wax Filled for Ultrafine Filigree,

Discover unparalleled precision with the SuperCast 8K 3D Printer Resin Wax Filled, designed specifically for creating intricate jewelry pieces. Crafted to deliver strong, detailed prints, it empowers users to produce ultrafine filigree patterns effortlessly.

This resin stands out with its unique wax-filled formulation, which burns out cleanly at lower temperatures. It caters to creatives demanding high-resolution output without complexity in the post-processing stage.

The SuperCast resin offers an exceptional blend of strength and stiffness, making it ideal for delicate jewelry designs. Thanks to its low viscosity, it supports 8K resolution printing with crisp detail down to 22 microns, ensuring clarity at every curve and edge.

Compatibility is broad, working seamlessly with all types of regular and mono LCD 3D printers. Its advanced photosensitization technology optimizes curing without requiring further post-curing steps, which can harm the burn-out process.

Users benefit from a clean burnout process that leaves no ash residue, even at lower temperatures, making mold preparation easier and quicker. This feature also eliminates the need for specialized ovens or kilns, simplifying jewelry casting workflows.

Its compact size and lightweight packaging enhance handling and storage convenience. SuperCast resin suits professional jewelers and hobbyists aiming for the best 3D wax printer results in fine-detail applications. The balance between precision, ease of use, and reliable performance delivers excellent value for crafting exquisite pieces.

Pros

- Wax-filled resin ensures strong, ultrafine filigree prints.

- Burns out completely at low temperatures without ash traces.

- Compatible with all regular and monochrome LCD 3D printers.

Cons

- Requires careful handling to avoid improper post-curing that may impair burnout.

SuperCast 8K resin strikes a fine balance between precision and practical use for jewelry makers. Its design for flawless burnout and unmatched detail makes it a reliable choice for fine casting needs, outperforming standard resins in both efficiency and output quality.

3. Siraya Tech Cast 3D Printer Resin Easy to Print Use

The Siraya Tech Cast 3D Printer Resin offers a reliable solution for jewelry makers and small metal part producers. Designed with ease of use in mind, this resin delivers impressive print detail without the need for complicated preparation or special environments.

Its castable properties make it particularly suitable for precision casting, ensuring smooth burnouts and crisp results. Combining functionality and quality, it caters to both beginners and seasoned users seeking refined prints.

Crafted with a wax-containing formula, the resin burns out with ease, minimizing leftover residue during casting. This characteristic enhances workflow efficiency, especially for intricate jewelry pieces where precision is paramount.

Its unique purple hue not only looks appealing but also indicates the high resolution that users can expect. The smooth surface finish and fine detail reproduction contribute to professional-grade prototypes and final products.

Compatibility with most LCD and DLP 3D printers allows for versatile use across different machines without hassle. Fast curing times and strong plate adhesion help reduce print errors and increase overall reliability, making it accessible for users at various skill levels.

Effortless printability combines with consistent performance to enable quick model production. The resin’s adaptability across applications includes jewelry manufacturing, dental models, and small functional metal parts — showcasing its broad utility.

Post-processing is straightforward, although proper cleaning and curing steps must be followed to ensure optimal cast burnouts. While some users report a learning curve with settings and cleanup, the final results can match or exceed expectations when handled methodically.

Pros

- Easy to burn out cleanly due to wax content

- High-resolution prints with smooth surfaces

- Compatible with most LCD and DLP 3D printers

Cons

- Requires careful post-processing to avoid resin buildup

Overall, the Siraya Tech Cast resin combines precision and practicality in casting applications. Its performance and versatility make it a valuable choice for makers seeking detailed and easy-to-use 3D printing resin suitable for jewelry and other small metal parts.

4. Siraya Tech Cast 3D Printer Resin Easier to Burn and

Siraya Tech Cast 3D Printer Resin delivers exceptional results for jewelry makers requiring precision and clarity. Its unique wax-containing formula enhances burnability, making it a reliable companion for casting detailed metal parts.

Ideal for intricate designs like bracelets and medals, the resin offers smooth surface quality and impressive resolution. Whether you’re new to 3D printing or experienced, this resin supports quicker, cleaner prints with less hassle.

Crafted for ease of use, the resin performs well without the need for controlled environments or additives. It adheres firmly to print plates and enables high-resolution outputs suitable for jewelry and dental models. The bright true blue color not only enhances print clarity but also highlights fine details with a glossy finish.

The resin is softer compared to alternatives, which allows it to capture complex shapes and ultra-fine features. It burns out cleanly with minimal ash, making post-processing efficient and improving casting quality.

Its compatibility spans most LCD, DLP, and SLA printers, broadening its usability beyond niche equipment.

Compared to other castable resins, Siraya’s True Blue formula strikes a balance of rigidity and burnability, aiding both model stability and clean casting. It fits users seeking reliable results in thicker, more demanding jewelry designs, without compromising printing speed or detail.

Pros

- Contains wax for easier, cleaner burnout with less residue.

- High resolution with smooth surface finish enhances jewelry detail.

- Works well in various 3D printers without special environment needs.

Cons

- Models are fragile before post-curing, requiring careful handling.

Siraya Tech Cast resin combines precision, ease, and clean burnout for jewelry 3D printing. Its versatility and quality make it a solid choice for both beginners and experienced users aiming for detailed, reliable castings.

5. Siraya Tech Cast 3D Printer Resin Easy to Print Use

Discover the Siraya Tech Cast 3D Printer Resin, designed specifically for creating fine jewelry and small metal parts. Its unique blend delivers excellent printing precision while simplifying the casting process.

Whether you are new to 3D printing or experienced, this resin’s user-friendly formula ensures straightforward printing without special additives or extreme environmental controls. The impressive adhesion and smooth finish help bring intricate designs to life with ease.

Siraya Tech Cast resin stands out thanks to its wax-based composition, which allows for easier burnout during casting. This characteristic reduces the likelihood of casting defects, offering jewelers a reliable material for producing high-quality metal pieces. Models printed with this resin exhibit a sharp resolution and striking purple color, making details crisp and visible.

Models printed with this resin exhibit a sharp resolution and striking purple color, making details crisp and visible.

The resin supports fast printing speeds and works flawlessly with most LCD or DLP 3D printers, including 8k-capable devices. Preparation and post-processing are straightforward, requiring fewer steps than many comparable casting resins.

This combination of high performance and ease of use makes it ideal for jewelers, engineers, and dentists alike.

While the purple resin offers solid results, some users have reported better ease of printing and cleaner burnout when mixing it with Siraya’s blue resin. Infusing flexibility in your printing approach can enhance reliability and final model strength. Overall, this resin balances fine detail with practical handling for a versatile, dependable printing experience.

Overall, this resin balances fine detail with practical handling for a versatile, dependable printing experience.

Pros

- Wax-based formula simplifies burnout, reducing casting defects.

- High resolution delivers precise details and smooth model surfaces.

- Compatible with most LCD/DLP 3D printers including 8K models.

Cons

- Requires careful calibration to avoid resin buildup around supports.

Offering a blend of excellent print quality and efficient casting capabilities, the Siraya Tech Cast 3D Printer Resin meets the needs of professionals crafting intricate pieces. Its ease of printing combined with high detail fidelity makes it a solid choice for those seeking dependable castable resin options.

6. SUNLU 10K Red Wax 3D Printer Resin, High Precision 405nm

Experience exceptional precision and smooth detailing with the SUNLU 10K Red Wax 3D Printer Resin. Tailored specifically for jewelry design, its vivid red wax matte finish brings out intricate features with stunning clarity. Whether creating prototypes or final pieces, this resin offers reliability and visual appeal.

Whether creating prototypes or final pieces, this resin offers reliability and visual appeal.

Designed to provide enhanced stability and minimal shrinkage, the resin supports flawless prints that resist deformation. Low-odor properties make the printing process comfortable, while wide compatibility ensures it works with most resin 3D printers in the market.

The SUNLU 10K Red Wax Resin stands out by delivering sharp surface details that showcase every contour of your jewelry models. Its improved liquidity and toughness provide ease during handling and post-processing, making your workflow much smoother. After curing, the vivid red color remains true, maintaining the authentic look of wax in your designs.

Stability plays a key role in preserving the integrity of printed items. This resin minimizes volume shrinkage to keep models intact without cracking or warping. It is user-friendly with a lower odor level, creating a pleasant printing environment compared to typical resins.

Cleaning prints with alcohol or ethanol is straightforward, adding convenience to finishing tasks.

Compatible with a broad range of SLA and DLP 3D printers, the SUNLU resin adapts well across different machine setups. It is especially suitable for jewelers and designers seeking precise wax patterns for casting and molding.

Investments in quality printing materials like this resin can significantly elevate the detail and realism of your work.

Pros

- Superior accuracy with 10K resolution for detailed jewelry models

- Improved toughness and liquidity for easier handling and printing

- Low odor formula creates a comfortable working environment

Cons

- Limited color options beyond the distinctive red wax finish

The SUNLU 10K Red Wax 3D Printer Resin is a reliable choice for crafting high-precision jewelry prototypes and casting models. Its ability to retain fine detail with enhanced stability makes it a smart addition to any jewelry maker’s toolkit.

7. Castable 3D Printer Resin, High-Temperature Resistance Resin for Jewelry and

Discover a resin specially formulated for precision in jewelry making, offering exceptional detail and reliable casting outcomes. Crafted to meet the stringent demands of jewelry creators, it supports both small studios and commercial workflows with ease.

Experience smooth mold filling and high-temperature resistance, ensuring flawless castings each time. Combining excellent flow characteristics and ultra-low ash content, it captures intricate designs with clarity and minimal cleanup required.

Castable 3D Printer Resin presents a streamlined printing process tailored for intricate rings, pendants, and detailed jewelry components. Its formula supports quick UV curing and offers excellent flow properties without the need for additives or controlled drying.

The ultra-low ash content is key to producing clean burnouts, preserving every delicate detail and surface texture essential for professional-grade jewelry. Its compatibility extends to most LCD, DLP, and MSLA resin printers, broadening accessibility for different users and printer models.

In terms of performance, the resin stands out by delivering sharp, accurate reproduction of complex patterns. Customers appreciate its balanced odor levels and remarkable print quality when optimized properly. Although washing can require some effort, the final results justify the process, making it a valuable asset for jewelers aiming for high precision.

Pros

- Exceptional detail reproduction for complex jewelry designs

- Ultra-low ash formula ensures clean and flawless castings

- Compatible with most LCD, DLP, and MSLA 3D printers

Cons

- Cleaning requires more effort compared to standard resins

Combining superior detail capture and proven casting performance, this resin is a dependable choice for creators seeking precision and reliability in jewelry production. It balances ease of use with professional standards, making it a valuable material for detailed 3D wax printing.

8. Castable Resin for Jewelry and Metal Making – Premium High-Wax,

For jewelry and metal artisans aiming for precision, the Castable Resin for Jewelry and Metal Making offers exceptional reliability and detail. Designed to streamline the process from 3D printing to metal casting, this resin stands out for its superior burnout performance and fine detail capture.

Its specialized high-wax formulation guarantees minimal residue and flawless castings. Whether crafting delicate or bold designs, this resin supports both small workshops and larger production settings with consistent quality.

This castable resin features an 80% wax content, promoting clean combustion that leaves minimal ash after burnout. Such efficiency supports exact mold replication and reduces cleanup time between production stages. Its flow properties and fast curing times improve print speed and reduce failed prints, enabling greater productivity during jewelry creation.

The formula preserves intricate surface textures and sharp edges, capturing every nuance critical for detailed rings, pendants, and complex geometries. Compatibility across LCD, DLP, and MSLA printers broadens its use among diverse printing platforms without sacrificing outcome quality.

Handling and curing are straightforward, though washing the resin requires a bit more effort compared to standard resins. Nevertheless, the flawless finish and reduced casting defects justify the extra care. It’s an excellent choice for professionals focused on high-definition results and efficient workflows in metal casting projects.

It’s an excellent choice for professionals focused on high-definition results and efficient workflows in metal casting projects.

Pros

- High 80% wax content ensures clean burnout with minimal residue

- Excellent detail reproduction for intricate and precise jewelry designs

- Fast curing and optimized flow promote efficient printing and productivity

Cons

- Requires more effort for thorough washing compared to standard resins

A reliable castable resin designed to deliver fine detail and smooth casting results, making it ideal for jewelry makers seeking accuracy and clean workflows. It delivers a clear advantage in quality compared to typical castable resins, especially for professional-level creations.

9. Formlabs True Cast Resin for 3D Printers – High Precision

Achieve flawless jewelry casting with the Formlabs True Cast Resin for 3D printers. This resin is crafted to deliver exceptional precision and smooth surface finishes, making it ideal for detailed designs. Its advanced formulation supports high-quality investment casting without compromising accuracy.

Designed for durability and reliability, the resin ensures consistent performance even during complex casting tasks. Perfect for creating intricate jewelry or engineering components, it maintains its integrity throughout the printing and casting process.

Formlabs True Cast Resin stands out with its ability to produce prints featuring crisp details and smooth surfaces that require minimal post-processing. The low expansion rate during casting avoids common issues like wax migration or surface degradation.

This resin guarantees a clean burnout thanks to its ultralow ash content of only 03%, which prevents residue buildup during investment casting workflows.

The formulation supports precise printing for parts up to 5mm thick, making even the most demanding jewelry patterns achievable. Each print maintains structural stability over time, granting a more forgiving and efficient casting experience.

Its compatibility with various specialized casting processes benefits artisans and manufacturers alike.

Built to integrate seamlessly with existing investment setups, True Cast Resin balances performance with ease of use. Its consistent quality reduces the risk of defects during the casting stage and supports reliable batch production.

Pros

- High precision with crisp, detailed prints and smooth surfaces

- Low expansion and no wax migration ensures stable casting results

- Extremely low ash content for clean burnouts in investment casting

Cons

- Limited to parts up to 5mm thickness, which may restrict some applications

For professionals seeking a reliable and precise resin tailored to jewelry casting, Formlabs True Cast Resin delivers consistent results without compromising detail or surface quality. Its clean burnout and compatibility with existing workflows provide an advantage over many standard casting materials, making it a smart choice for refined 3D printing projects.

10. Antinsky Castable Jewellery Smart Resin for DLP LCD UV-Curing 405nm

Antinsky Castable Jewellery Smart Resin offers a reliable resin solution designed specifically for precision 3D printing in jewelry creation. Its formulation ensures detailed, high-quality prints that meet the demands of professional and hobbyist jewelers alike.

With compatibility for DLP and LCD printers emitting UV light at 405nm, this resin combines strength with fine detail. Whether crafting intricate designs or durable castings, it supports creativity and efficiency in jewelry production.

The resin features a performance viscosity balanced between 70 and 180 mPa·s, ensuring smooth flow and consistent layer formation during printing. Density ranges from

05 to 25 g/cm3, giving prints the necessary heft for handling and post-processing tasks. Mechanical properties such as tensile strength up to

88 MPa and elongation at yield point near 47% contribute to its robustness.

Printing parameters include layer thickness settings from 02 to 05 mm and normal exposure times of 8 to 12 seconds.

05 mm and normal exposure times of 8 to 12 seconds. The resin’s absorption band between 385 and 410 nm aligns well with most 405nm UV light sources, ensuring efficient curing. The bottom exposure time ranges from 40 to 50 seconds, promoting strong adhesion in early layers.

Effortless to use, the resin enables sharp details and solid structures without extensive trial and error. However, post-processing may require attention due to occasional sticky residue after burnout. Despite this, the resin burns out cleanly without expansion or breakage, maintaining integrity for casting purposes.

Despite this, the resin burns out cleanly without expansion or breakage, maintaining integrity for casting purposes.

Pros

- Produces sharp, highly detailed prints with strong mechanical properties.

- Compatible with popular DLP and LCD UV-curing 3D printers (405nm).

- Offers consistent performance with a well-regulated viscosity and curing profile.

Cons

- Post-processing can be challenging due to sticky residue affecting investment interaction.

Antinsky Castable Jewellery Smart Resin stands out as a solid choice for jewelry professionals seeking detailed prints and structural durability. Its printing ease and compatibility with common 3D printers make it versatile, although some attention during burnout is needed. Compared to similar resins, it offers a dependable balance of quality and strength worth considering.

11. Phrozen AnyCast Jewelry Castable 3D Printing Resin, 60% Wax Content

Phrozen AnyCast Jewelry Castable 3D Printing Resin offers precision and reliability designed specifically for jewelry creation. Ideal for crafting intricate designs, it combines a high wax content that enhances casting results and minimizes ash buildup.

Perfect for a range of jewelry items, this resin guarantees detailed reproductions in every print. Its formulation focuses on smooth surface finish and ease of use during post-processing.

This resin features 60% wax content, providing excellent burnout performance and resulting in clean, ash-free castings. Its ability to accurately capture fine details makes it suitable for delicate wedding bands and bold statement pieces alike. The smooth surface finish aids in polishing and reduces finishing time.

The smooth surface finish aids in polishing and reduces finishing time.

Designed to handle medium to large jewelry items, the resin resists cracks and warping, maintaining structural integrity throughout casting. Its low odor ensures a comfortable workspace while simplifying cleanup. The resin works well with various 3D printers, streamlining the transition from print to finished piece.

Overall, it combines high precision, strong performance, and user-friendly handling for jewelers focused on quality and efficiency.

Pros

- High wax content ensures minimal ash residue for clean castings

- Excellent detail reproduction for intricate and bold jewelry designs

- Resistant to cracks and warping on medium to large pieces

Cons

- Available only in specific package sizes, limiting bulk options

Phrozen AnyCast resin balances detail, reliability, and ease of use, making it a strong choice for jewelers seeking superior 3D printing results. Its formulation stands out in castable resins by delivering clean, precise molds with minimal post-processing effort.

12. Antinsky W80 Castable Jewellery Resin for DLP LCD UV-Curing 405nm

Crafted specifically for jewelry casting, the Antinsky W80 Castable Jewellery Resin offers unmatched clarity and precision. Its pure white tone allows for easier inspection of fine details, helping to perfect every design before forging.

With high resolution and excellent thermal stability, this resin supports accurate and clean burnouts. It is compatible with a wide range of 405nm DLP, LCD, and SLA 3D printers, making it a versatile addition to your jewelry-making toolkit.

The Antinsky W80 resin excels in producing detailed, thick jewelry models such as bracelets, large pendants, medals, and coins. It contains wax for quick and clean burning, which reduces ash residue and streamlines the casting process. This quality is especially valuable when working with larger or more complex pieces.

This quality is especially valuable when working with larger or more complex pieces.

Models printed with this resin maintain dimensional stability due to its low thermal expansion coefficient. This minimizes deformation during the burnout phase, ensuring precision at every step.

Applying this resin involves a clear post-processing procedure, including alcohol soaking, boiling water treatment, and UV curing. Users appreciate the balance of excellent print clarity and practical ease in cleaning.

Pros

- Very high resolution for detailed jewelry models

- White color enhances visibility of fine design features

- Wax content enables fast, ash-free burnout for clean casting

Cons

- Users report the necessity for precise technique to avoid imperfect results

Overall, the Antinsky W80 Castable Jewellery Resin stands out as a reliable choice for creating accurate and highly detailed castable models. It offers notable advantages in visibility and burnout quality, suited for those prioritizing detail and precision in jewelry production.

13. Antinsky Castable Jewellery Resin for DLP LCD UV-Curing 395-405nm Resin

Antinsky Castable Jewellery Resin delivers precision and reliability for 3D printing fine jewelry wax patterns. Designed with a high wax content, it ensures complete combustion and ash-free results, perfect for clean casting processes.

Its compatibility with various casting materials and improved formula provide excellent durability. This resin stands out for ease of use and is well-suited for users working with DLP and LCD UV curing printers. It promises sharp results with consistent performance during every print.

It promises sharp results with consistent performance during every print.

Crafted to cater specifically to jewelry casting demands, the Antinsky resin combines 75% wax content for clean burnout with outstanding hardness at 75D. Models print with crisp details and retain their shape through the casting process, minimizing defects.

The resin’s toughness extends tensile strength and elongation for better handling during mold making.

The improved formula lowers fluidity to enhance printing precision on low-energy LCD and DLP printers. Its compatibility with high-quality gypsum ensures jewelry casts gain smooth finishes and reduced expansion errors. Fast curing speeds particularly benefit users working with black and white LCD screens, shortening wait times without sacrificing quality.

Ideal for professional jewelers and designers requiring reliable burnable patterns, this resin provides both flexibility and precision. Its consistent performance across various paraffin casting workflows sets it apart from generic resins, helping users achieve flawless results with less post-processing effort.

Pros

- High wax content ensures complete ash-free combustion

- Excellent toughness with improved tensile strength and elongation

- Fast curing speed optimized for DLP and LCD printers

Cons

- Viscosity adjustment may require printer setting fine-tuning for best results

Antinsky Castable Jewellery Resin is a dependable choice for producing precise and robust wax patterns. Its balance of detail clarity and clean burnout supports efficient casting processes, making it a valuable material for jewelers focused on quality and consistency.

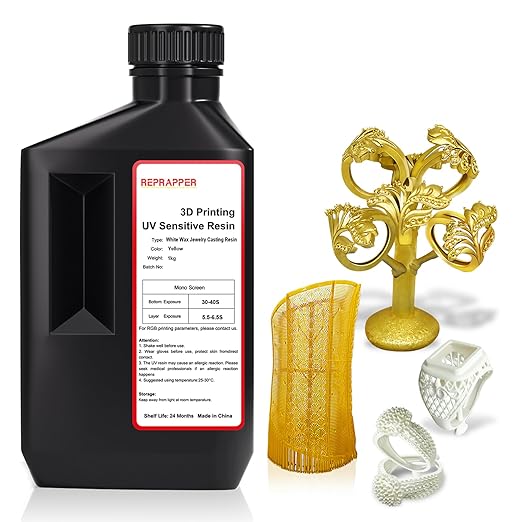

14. Reprapper White-Wax Casting 3D Printer Resin, Castable LCD UV-Curing 1kg

Reprapper White-Wax Casting 3D Printer Resin offers exceptional results for jewelry makers aiming for precision and smooth finishes. Designed specifically for high-quality casting, this resin delivers the detail and reliability needed for professional-grade projects.

By combining advanced wax formulas with easy burn-out properties, it streamlines the jewelry creation process. Whether you work with a range of 3D printers or seek consistent dimensional accuracy, this resin adapts effortlessly.

Crafted with a unique recipe incorporating special wax, this resin produces a smooth film that enhances metal flow during casting. Its high wax content ensures cleaner results without ash residue or bubble noise after burn-out. The simple

33℃/min ramp-up curve means less time and effort are needed to achieve successful burn-outs.

Dimensional stability is a key feature, maintaining precision throughout UV curing and minimizing distortions during the printing process. Compatible with popular 405nm LCD and DLP 3D printers such as B9C, Phrozen, Elegoo, and Anycubic models, it suits a wide range of hobbyists and professionals.

Post-curing leads to a pure white finish, allowing defects to be easily identified before casting. These characteristics streamline production, improve accuracy, and support enhanced jewelry craftsmanship without requiring complex oven settings.

Pros

- High wax formula ensures smoother metal flow with less casting defects

- Burns out cleanly with no ash residue or bubble noise

- Excellent dimensional stability during UV curing and faster burn-out time

Cons

- May soften certain types of plastics during cleaning

Reliable and versatile, this 3D printing casting resin enhances jewelry production quality while saving time and energy. Its compatibility and ease of use make it a strong choice for makers seeking detailed and consistent casting results.

15. Cast100P Castable 3D Printer Resin, 405nm UV Curing High Precision

Experience precision and reliability with the Cast100P Castable 3D Printer Resin. Specifically formulated for jewelry design, this resin offers exceptional detail and smooth finishes.

It helps transform creative ideas into tangible models with remarkable accuracy.

Designed to work seamlessly with 405nm UV curing 3D printers, the jewel-green Cast100P resin supports flawless burn-out casting. This makes it perfect for crafting intricate, high-quality jewelry pieces that demand precision and fine detail.

The Cast100P resin stands out with its ultra-high resolution, capturing even the smallest design elements. Its stable dimensional properties reduce distortion during casting, which means your printed models remain true to their original form. This stability is crucial for maintaining the integrity of complex jewelry creations.

Engineered with low-odor raw materials, it ensures a more pleasant printing environment and is easier to clean up. The resin’s wax content allows for cleaner burnouts with minimal ash residue, facilitating smoother casting preparations and fewer post-process issues. Compatibility is broad, fitting most 405nm wavelength DLP and LCD 3D printers, which offers flexibility for various users.

Compatibility is broad, fitting most 405nm wavelength DLP and LCD 3D printers, which offers flexibility for various users.

Whether you’re verifying designs or producing final models, Cast100P meets the demands of meticulous craftwork. Its blend of precision, clean combustion, and ease of use presents significant advantages over many standard castable resins.

Pros

- Exceptional high resolution for detailed jewelry models

- Dimensional stability minimizes distortion during burn-out casting

- Low odor and easy to wash, improving printing comfort

Cons

- Requires specific settings for optimal print quality, needing some calibration

Cast100P delivers a high level of accuracy and ease in jewelry modeling. It supports detailed artistry and efficient casting processes, making it a valuable choice for those seeking quality resin solutions tailored for precision jewelry printing.

Unlock Precision and Creativity: Your Ultimate Guide to the Best 3D Wax Printers for Jewelry Making

Durability and maintenance

When selecting the best 3d wax printer for jewelry, paying attention to the reliability and build quality of the machine greatly impacts how well it performs over time. A well-constructed printer made from sturdy materials ensures consistent results and minimizes unexpected breakdowns. Ease of maintenance plays a significant role in keeping the printer functioning smoothly; models designed with accessible parts and straightforward replacement procedures reduce downtime and simplify upkeep.

Access to responsive customer support and service options also adds peace of mind by providing assistance when technical issues arise or when guidance is needed for optimal use. Together, these factors contribute to a hassle-free experience, making it easier to focus on crafting detailed wax models without interruption.

Speed and efficiency

When searching for the best 3d wax printer for jewelry, paying close attention to speed and efficiency can greatly impact your overall workflow. A printer that offers a fast print speed without compromising quality helps produce detailed wax models more quickly, allowing jewelers to meet client demands and reduce project turnaround times.

Printers that come with intuitive software and simple setup processes can simplify the design-to-print journey, minimizing downtime and learning curves. Additionally, considering postprocessing time and complexity is wise because a model that requires minimal cleanup or finishing work can save a considerable amount of effort and time, increasing productivity.

Balancing these factors results in a smoother production experience and efficient creation of intricate wax prototypes suitable for casting.

Build volume and size

The maximum print size and capacity of the best 3d wax printer for jewelry plays a significant role in determining which jewelry designs can be created effectively. Printers offering sufficient print dimensions allow for crafting a range of pieces from delicate rings to intricate pendants and even larger statement items without compromising detail or structural integrity. Considering the suitability for different jewelry pieces, smaller printers excel at producing fine, detailed components ideal for traditional rings and earrings, while those with larger capabilities accommodate more complex or bold designs.

Alongside print capacity, the physical dimensions of the printer itself influence workspace requirements, especially for smaller studios or home setups. A compact footprint lends itself well to limited spaces, whereas larger machines need more room but provide expanded creative possibilities.

Balancing the printer’s size with its output capabilities ensures both convenience and versatility when designing jewelry components.

Print quality and resolution

When selecting the best 3d wax printer for jewelry, paying attention to layer height and detail precision is vital for achieving intricate designs that require fine accuracy. Jewelry pieces often feature delicate patterns and small components, so a printer capable of handling minimal layer thickness will produce detailed results that capture these complexities faithfully.

Additionally, surface smoothness of wax prints plays a significant role since a smoother finish reduces the need for extensive post-processing and polishing, saving time and effort. Printers designed with advanced calibration and stable mechanics tend to yield wax prints with fewer imperfections, supporting the production of jewelry that meets high standards of craftsmanship.

Considering these features alongside the intended use, whether for prototyping, direct casting, or production-grade models, helps make an informed choice that aligns with both creative goals and practical requirements.

Printer technology and compatibility

When choosing the best 3d wax printer for jewelry, understanding the types of 3d printing technologies available can help in making an informed choice. Technologies like digital light processing (DLP) and stereolithography (SLA) are commonly used for producing detailed, high-resolution wax models suitable for intricate jewelry pieces.

In addition to technology, considering the wax and resin materials compatible with the printer is another key factor, as different printers support various formulations that affect the hardness, melting point, and fine detail reproduction critical for jewelry casting. Equally important is the printer’s compatibility with computer-aided design (CAD) software prevalent in jewelry design, enabling smooth workflow integration from digital model creation to physical prototype.

Ensuring that the printer supports standard file formats and interfaces easily with popular CAD tools will streamline the design process and reduce delays. Overall, balancing technology type, material support, and software compatibility contributes to selecting a 3d wax printer well-suited for crafting beautiful jewelry pieces efficiently and accurately.

Cost and value

When selecting a 3d wax printer for jewelry, evaluating the initial investment alongside ongoing expenses is vital to making a sound purchase. The upfront cost often reflects the printer’s precision, build volume, and speed, which directly affect production quality and efficiency.

These materials contribute significantly to the total operational budget and can vary depending on the printer model and manufacturer. Considering your production needs will help determine the return on investment; smaller operations might find compact printers with moderate consumable costs more suitable, whereas larger-scale production could justify a higher initial investment for faster output and better durability.

Balancing these factors ensures that the printer aligns well with both budget constraints and manufacturing goals, making the purchase both practical and profitable over time.

FAQ’s

What Are The Key Features To Look For In The Best Wax Printer For Jewelry?

The best wax printer for jewelry should offer high precision and fine detail to accurately create intricate designs, along with compatibility with various wax materials. Additionally, it should have reliable durability and user-friendly software for seamless customization.

How Do The Top Wax Printers Compare In Terms Of Printing Speed And Material Compatibility?

Top wax printers generally offer fast printing speeds suitable for high-volume production, with some models reaching up to several meters per minute. In terms of material compatibility, they excel at printing on a wide range of fabrics and plastics, making them versatile for various industrial applications.

What Is The Typical Price Range For The Best Wax Printers Used In Jewelry Making?

The typical price range for the best wax printers used in jewelry making is between $5,000 and $20,000. High-end models with advanced features can cost upwards of $30,000.

Which Wax Printers Offer The Highest Precision For Intricate Jewelry Designs?

Wax printers like the Solidscape S350 and the EnvisionTEC Perfactory series offer the highest precision for intricate jewelry designs. These printers utilize advanced micro-stereolithography technology to achieve fine detail and smooth surface finishes essential for jewelry molds.

Are There Any Recommended Wax Printers Specifically Designed For Small-Scale Or Custom Jewelry Production?

Yes, there are wax printers like the Roland DWX series and the Formlabs Form 3 that are popular for small-scale or custom jewelry production due to their precision and ability to create detailed wax patterns. These printers are designed to meet the intricate requirements of jewelry making, providing high accuracy and smooth finishes.

Conclusion

Choosing the best 3d wax printer for jewelry involves balancing precision, ease of use, and material compatibility. These printers excel at producing highly detailed wax models essential for intricate jewelry designs, making them ideal for small businesses or individual designers focused on quality craftsmanship. While some models may come with a higher upfront cost or require a learning curve, their ability to streamline the prototyping process and reduce manual errors often justifies the investment.

While some models may come with a higher upfront cost or require a learning curve, their ability to streamline the prototyping process and reduce manual errors often justifies the investment. Anyone seeking reliable accuracy and efficient workflow will find these printers valuable. Ultimately, selecting the right 3D wax printer depends on your specific production needs and budget, but prioritizing features that support fine detail and repeatability will lead to the best results in jewelry creation.