Steppers are a key component in 3D printers, controlling the precise movement of the print head and build platform. Choosing the right driver for these motors can make a noticeable difference in print quality and reliability. The best 3d printer stepper driver offers smooth operation, quieter performance, and better heat management.

The best 3d printer stepper driver offers smooth operation, quieter performance, and better heat management. This type of component suits anyone looking to improve their 3D printing experience, whether upgrading a current machine or building a custom setup. This review will look at several popular stepper drivers, comparing their features, compatibility, and value.

It aims to help you find a driver that balances performance with durability, without overwhelming you with technical jargon. By the end, you’ll have a clearer idea of which model fits your specific needs and printer type.

| Image | Name | Our Rating | Price |

|---|---|---|---|

|

BIGTREETECH TMC2209 V1.3 UART Stepper Mo...

|

|

|

|

HiLetgo 5pcs A4988 Stepstick Stepper Mot...

|

|

|

|

BIGTREETECH Direct BIGTREETECH TMC2209 V...

|

|

Unlocking Precision: Top Controllers That Elevate Your 3D Printing Experience

| Image | Product | Price |

|---|---|---|

Our Top Picks 1  | BIGTREETECH TMC2209 V1.3 UART Stepper Motor Driver 2.8A Peak Stepstick | Buy Now |

Our Top Picks 2  | HiLetgo 5pcs A4988 Stepstick Stepper Motor Driver Module with Heat | Buy Now |

Our Top Picks 3  | BIGTREETECH TMC2209 V1.3 Stepper Motor Driver, UART/STEP/DIR Mode, Ultra Silent | Buy Now |

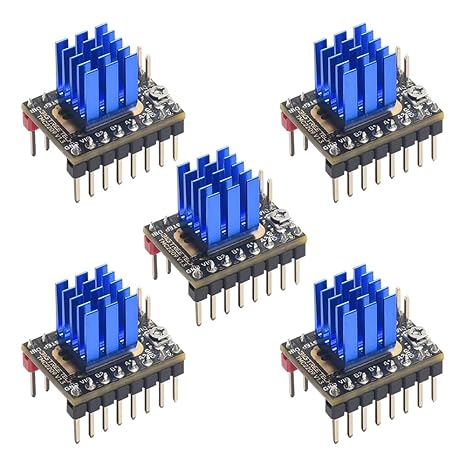

1. BIGTREETECH TMC2209 V1.3 UART Stepper Motor Driver 2.8A Peak Stepstick

Experience smooth and silent stepper motor control with the BIGTREETECH TMC2209 V1.3 UART Stepper Motor Driver.

Its innovative features support enhanced thermal management and motor stability for consistent performance.

Engineered for advanced 3D printing needs, the TMC2209 V1.3 offers multiple operation modes including STEP / DIR and UART. The driver’s large thermal pad effectively lowers operating temperature, preventing overheating during intensive tasks.

Stall detection functionality adds a layer of protection by identifying motor stalls early, maintaining print quality and hardware safety.

The stepper driver is built with durability and efficiency in mind, supporting up to 8A peak current.

Its compatibility with common 3D printer motherboards allows easy integration and reliable performance. Assembly and setup are straightforward, making it suitable for both DIY projects and professional printers.

With a compact size of 82 x

32 x 26 inches and a lightweight build, it fits neatly into various printer configurations. Its ability to prevent motor shaking ensures higher print accuracy and smoother layer transitions.

Ideal for users seeking precise motor control and noise reduction, this driver stands out against standard stepper drivers by combining advanced features with user-friendly operation.

Pros

- Ultra-quiet operation minimizes printer noise.

- Built-in stall detection enhances print reliability.

- Large thermal pad reduces driver temperature effectively.

Cons

- Requires basic knowledge of stepper driver installation and UART configuration.

The BIGTREETECH TMC2209 V1.3 offers a solid balance of quiet performance, thermal management, and advanced features.

It suits users aiming for dependable stepper control and precision without added noise. Compared to other drivers, it excels in heat dissipation and operational smoothness, making it a valuable upgrade for many 3D printing setups.

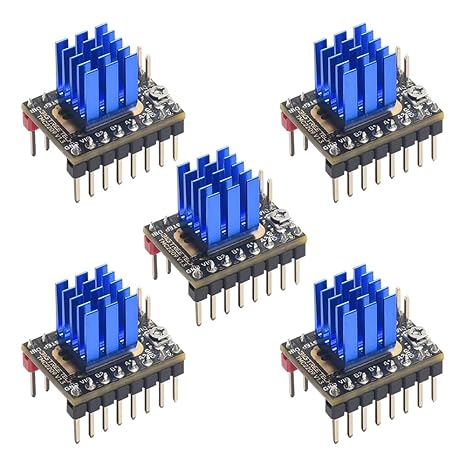

2. HiLetgo 5pcs A4988 Stepstick Stepper Motor Driver Module with Heat

Enhance your 3D printing projects with the HiLetgo A4988 Stepstick Stepper Motor Driver Module. This set of five modules delivers reliable motor control for precise and smooth operation.

Each driver offers adjustable current control and advanced protection features to safeguard your equipment. Its versatility in step resolution settings makes it highly adaptable for various stepper motors.

These stepper motor drivers are built to support voltages up to 35 V and currents of ±2 A, providing robust power delivery.

Intelligent chopping control automatically manages current decay mode for optimal operation.

Protection mechanisms include thermal shutdown, under-voltage lockout, and crossover-current protection, enhancing longevity and safety. Installation is straightforward with a simple interface, but static precautions are recommended to prevent damage.

The compact form factor fits easily into most 3D printer setups and CNC machines, avoiding issues seen with larger heatsink designs. Overall, it balances quality and functionality effectively, earning trust from users who have tested it over extended printing sessions.

Pros

- Supports multiple step resolutions for fine motor control

- Adjustable current output via built-in potentiometer

- Comprehensive protection including thermal and current safeguards

Cons

- Requires anti-static precautions during handling

Reliable and adaptable, the HiLetgo A4988 Stepstick offers consistent performance suited for 3D printers and CNC applications. Its proven design and protection features make it a practical choice for users seeking efficient motor driver modules.

3. BIGTREETECH TMC2209 V1.3 Stepper Motor Driver, UART/STEP/DIR Mode, Ultra Silent

BIGTREETECH TMC2209 V1.3 Stepper Motor Driver offers ultra-silent operation with advanced motor technology.

This driver is tailored for 3D printers that demand quiet and reliable performance.

Its cutting-edge Stallguard4 sensorless homing eliminates the need for physical limit switches. Compatibility with popular motherboards ensures broad usability. Users benefit from enhanced printing accuracy and noise reduction, making every print job more enjoyable and professional.

Users benefit from enhanced printing accuracy and noise reduction, making every print job more enjoyable and professional.

The TMC2209 stepper driver combines innovative features with solid build quality. It operates quietly thanks to StealthChop2 technology, reducing motor noise significantly compared to older drivers. Voltage support ranges from

75V to 28V, accommodating various printer setups and motor types.

Sensorless homing allows axis limits to be detected without additional hardware, simplifying printer design. UART and STEP/DIR communication modes offer flexibility, but enabling UART requires firmware adjustments detailed in the official BIGTREETECH GitHub resources.

It replaces noisy or less efficient drivers such as TMC2100, A4988, and DRV8825 effortlessly. The installation is straightforward, and comprehensive manuals are available online.

Pros

- Ultra-silent operation with StealthChop2 technology for noise reduction

- Supports sensorless homing via Stallguard4, eliminating limit switches

- Compatible with a wide range of popular 3D printer motherboards

Cons

- Requires firmware modification to enable UART mode

The BIGTREETECH TMC2209 V1.3 driver stands out as a cost-effective and quiet solution for stepper motor control. Its broad compatibility and advanced features make it a solid upgrade from standard drivers, especially for those prioritizing silent operation and smoother prints.

Its broad compatibility and advanced features make it a solid upgrade from standard drivers, especially for those prioritizing silent operation and smoother prints. Reliable performance and thorough documentation support a hassle-free experience.

4. BIGTREETECH TMC2209 V1.3 UART Stepper Motor Driver Module VS TMC2100

Experience quieter and more efficient 3D printing with the BIGTREETECH TMC2209 V1.3 UART Stepper Motor Driver Module. Designed to deliver smooth, silent motor operation, this driver sets a new standard in stepper control technology.

Designed to deliver smooth, silent motor operation, this driver sets a new standard in stepper control technology. It’s crafted for users seeking reliable and precise motion without the typical noise.

With advanced features like sensorless homing and excellent heat dissipation, the TMC2209 enhances the overall printing experience. Compatible with various popular 3D printer motherboards, it offers both flexibility and high performance.

This module stands out for those wanting smooth operation and energy saving in one compact package.

The BIGTREETECH TMC2209 combines stealthy motor control technology with robust current handling up to 8A peak. Thanks to StealthChop2 technology, motor noise is significantly reduced, making printing sessions nearly silent.

Its voltage range of 75V to 28V supports a wide variety of printers and motors.

This module integrates Stallguard4 locked motor sensorless homing, eliminating the need for physical limit switches. The innovative CoolStep dynamic current control cuts energy consumption by 75%, while also reducing heat generation. This improves both efficiency and longevity of your hardware.

Installation is straightforward with support for UART and STEP/DIR modes, though firmware modifications may be necessary depending on the configuration. The driver is compatible with numerous boards such as BTT Octopus and SKR Turbo. Users benefit from quiet, precise motion control with minimal troubleshooting.

Its solid PCB build ensures durability and stable performance over time.

Pros

- Ultra-quiet operation thanks to StealthChop2 technology

- Energy-efficient CoolStep current control reduces heat and power use

- Supports sensorless homing with Stallguard4 for simplified setup

Cons

- Requires firmware adjustments to switch between UART and STEP/DIR modes

The BIGTREETECH TMC2209 V1.3 is an excellent choice for users aiming to enhance their 3D printer’s motor control. It balances quiet operation with smart, energy-saving features and broad compatibility.

It balances quiet operation with smart, energy-saving features and broad compatibility. Those seeking quieter, more reliable stepper performance will appreciate this well-engineered driver module.

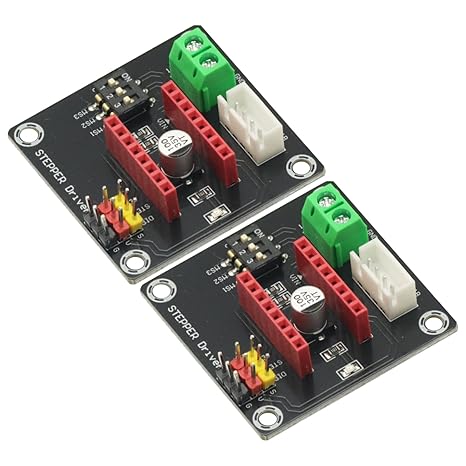

5. Jeanoko DRV8825/A4988 Stable 42 Stepper Motor Driver Expansion Board 3D

Jeanoko DRV8825/A4988 Stable 42 Stepper Motor Driver Expansion Board 3D delivers reliable and compact control for 42 stepper motors. Designed for seamless integration, it enhances the capability of 3D printers and DIY projects with steady performance and easy power connections.

This expansion board features an on-board DIP switch for simple segment adjustments, making operation efficient and user-friendly. Its compatibility with 12V and 24V drive schemes adds flexibility across various setups and applications.

The Jeanoko stepper driver expansion board offers a highly integrated design that saves space without sacrificing performance. Its terminal power connector simplifies the power supply connection, reducing installation hassle and improving stability.

Small in size yet professional in function, this board suits both beginners and experienced users seeking reliable stepper motor control.

Adjusting the drive segments with the DIP switch allows precise tuning tailored to individual project needs. Thanks to its compatibility with common voltage standards, it supports a wide range of 42 stepper motor drives and 3D printing systems. The robust build ensures consistent performance during extended machine operation.

Setup remains straightforward, though adding basic wiring and configuration guidance would enhance ease of use. This board represents a cost-effective upgrade for expanding stepper motor capacity beyond standard printer boards. It caters well to users modifying or expanding existing 3D printer setups and DIY electronics projects.

Pros

- On-board DIP switch enables easy segment adjustments

- Terminal power connector ensures stable and convenient wiring

- Compatible with both 12V and 24V drive schemes

Cons

- Lacks comprehensive wiring and configuration documentation

This stepper motor driver board stands out for combining reliability, compactness, and compatibility. It offers a practical solution for expanding motor control on 3D printers and DIY robotics, rewarding users who seek stable performance without complex setup.

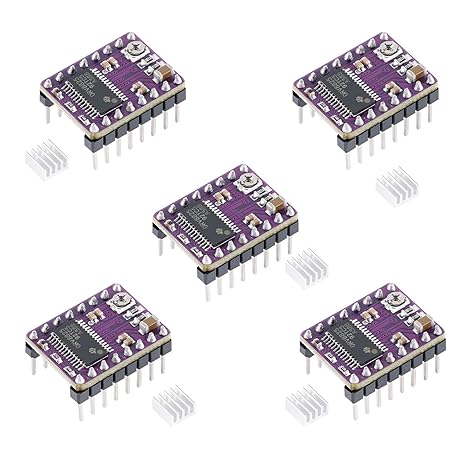

6. DRV8825 Stepper Driver, DRV8825 Stepper Motor Driver Module for 3D

Discover the DRV8825 Stepper Motor Driver, designed to enhance the precision and control of your 3D printer or CNC machine. This compact module offers advanced step resolution and high current capacity, making it a reliable choice for demanding motion control tasks.

Engineered to support a variety of bipolar stepper motors, the driver delivers smooth operation with microstepping capabilities up to 1/ Its improved thermal management extends the module’s durability during continuous use, providing stable performance across multiple applications.

The DRV8825 stepper motor driver module supports driving currents up to 5A and operates with input voltages as high as 45V.

These features contribute to quieter movement and higher printing resolution in 3D printers.

This driver is built with a 4-layer PCB board that enhances heat dissipation, ensuring it remains cool even under heavy workloads. Compared to the widely used A4988 driver, it provides better current handling, more microstepping options, and lower internal resistance, translating to reduced heat generation and increased efficiency.

Assembly quality benefits from surface-mount technology (SMT), offering stable and consistent performance without the need for manual soldering. The module’s compact dimensions allow easy integration into various models such as PrusaMendel, Ultimaker, and MakerBot. It also finds use in areas like robotics and office automation where precise motor control is necessary.

Pros

- Supports microstepping up to 1/32 for smooth and accurate motor movement

- Capable of delivering up to 2.5A current with effective heat dissipation

- Compact and compatible with many popular 3D printer models and CNC systems

Cons

- Some units may have inconsistent behavior and heat management issues

Overall, the DRV8825 Stepper Driver provides a feature-rich option for users needing precise stepper motor control. Its combination of microstepping capabilities and thermal design makes it a capable choice for various motor-driven projects.

7. 2Pcs 42 CH 42 Stepper Motor Driver Expansion Board for

Upgrade your 3D printer’s control system with the 2Pcs 42 CH 42 Stepper Motor Driver Expansion Board. Designed to support DRV8825 and A4988 drivers, it simplifies wiring and enhances motor performance.

This expansion board is perfect for creating precise and reliable stepper motor control in compact projects.

Engineered with a digital interface featuring direction, enable, and speed ports, it offers seamless compatibility with popular control shields. The board operates within a 12-30V input voltage range and requires a 5V logic voltage.

It comes equipped with a capacitor, screw terminals, and multiple ground connections, simplifying installation and improving stability. Suitable for controlling stepper motors smoothly, the compact design makes organization easier and reduces wiring clutter. Its reliable build supports consistent performance, helping maintain the accuracy vital in 3D printing and other motor-driven projects.

Effortless integration and clean wiring make this expansion board an excellent choice for those upgrading or repairing their printer’s stepper control system.

Pros

- Simplifies wiring with built-in capacitor and screw terminals

- Compatible with both DRV8825 and A4988 stepper drivers

- Supports stable operation within 12-30V input voltage range

Cons

- Limited to 42-stepper motor drivers and may not suit larger motor types

This expansion board offers streamlined wiring and solid compatibility for reliable stepper motor control. It enhances motor accuracy while keeping setups clean and manageable.

8. Teyleten Robot TMC2209 V2.0 Stepper Motor Driver StepStick 2.5A UART

Upgrade your 3D printer’s performance with the Teyleten Robot TMC2209 V2.0 Stepper Motor Driver StepStick. Designed for smooth, quiet, and efficient operation, this driver sets a new standard in stepper motor control.

Its advanced German TMC2209-TA chip delivers excellent muting effects that dramatically reduce noise during printing.

Built to handle input voltages from 5V to 28V, it ensures compatibility with various 3D printer setups. The large integrated heat sink enhances heat dissipation, maintaining optimal temperatures for consistent output.

This stepper driver supports sensorless feedback for precise motor control and improved reliability.

Built with high-quality metal material, the TMC2209 stepper driver offers durable construction ideal for long-term use. It supports speeds up to 50,000 RPM and operates quietly, which benefits users requiring noise reduction during long print jobs. The compact dimensions (

The compact dimensions (81 x 61 x

51 inches) make it easy to integrate within limited spaces.

Setup involves adjusting the VREF values for smooth operation, as users have found a range from 1V to 2V stable across different motor axes. Its UART communication simplifies firmware integration, particularly with Marlin

x, enhancing customization options without extra complexity.

Thanks to the sensorless homing feature, mechanical end stops can be avoided, adding convenience and reducing hardware wear. The device’s efficient heat management helps prevent overheating, contributing to consistent performance throughout long printing sessions.

Pros

- Excellent quiet operation thanks to the German TMC2209-TA chip

- Wide input voltage range from 5.5V to 28V for versatile use

- Supports sensorless feedback for advanced motor control

Cons

- Manual VREF adjustments are necessary for optimal performance

The Teyleten Robot TMC2209 V2.0 Stepper Motor Driver StepStick offers a balanced combination of silence, efficiency, and robust design. It fits well for users seeking improved print quality with quieter operation while maintaining firmware flexibility.

Its capacity for sensorless feedback makes it a strong choice compared to standard stepper drivers on the market.

9. 4PCS TMC2208 3D Printer Stepper Motor Driver TMC2208 V1.2 Stepstick

Discover quieter and smoother 3D printing with the 4PCS TMC2208 Stepper Motor Drivers. Designed to enhance your printer’s precision, these drivers significantly reduce noise during operation, offering a better overall printing experience.

Each driver provides advanced microstepping with 256 subdivisions, which allows for fine control of the stepper motors. The stealthChop2 technology ensures ultra-quiet operation, making it ideal for use in settings where noise reduction matters. These drivers aim to deliver reliable performance without requiring major hardware changes.

Engineered with the TMC2208 chip, these stepper drivers handle a continuous current of 4A and peak currents up to 2A, supporting most 3D printer motors efficiently.

75V to 36V makes them adaptable across different 3D printer setups. Installation is straightforward with stackable headers designed to fit directly onto standard printer boards.

The integrated microPlyer interpolation allows smooth sinusoidal control even where pulse frequencies are limited, enhancing print quality. The drivers are compatible replacements for models such as TMC2100, A4988, DRV8825, and LV8729, offering lower heat output and quieter operation. Users will appreciate the simple USB-to-serial flashing option for customizing or updating firmware.

Users will appreciate the simple USB-to-serial flashing option for customizing or updating firmware.

These drivers are especially suited for X, Y, and Z axes, providing excellent noise reduction and improved motor control. However, they are less optimal for extruder motors.

Pros

- Ultra-quiet operation with stealthChop2 technology

- Supports up to 256 microsteps for smoother motor control

- Compatible with popular stepper driver models for easy replacement

Cons

- Not recommended for extruder motor use

Offering advanced features and effortless installation, these TMC2208 stepper drivers are a reliable upgrade for reducing noise and improving motion precision in 3D printers. Their broad compatibility and efficient performance make them a valuable addition for many printing configurations.

10. Teyleten Robot 3D Printer Parts DRV8825 Stepper Motor Driver Module

Experience precise control and enhanced performance with the Teyleten Robot 3D Printer Parts DRV8825 Stepper Motor Driver Module. Designed for reliable operation, it simplifies step and direction control for smooth motor management.

Offering six different step resolutions, including whole, half, quarter, eighth, sixteenth, and thirty-second steps, it adapts perfectly to your motor control needs. The direct CAN interface supports both 3V and 5V systems, expanding compatibility options.

3V and 5V systems, expanding compatibility options. Thermal shutdown and overcurrent protection safeguard the device, enhancing durability during extended use.

The build incorporates a four-layer printed circuit board containing two ounces of copper to optimize heat dissipation effectively. This feature helps maintain steady performance in demanding environments. Setup is straightforward because the control interface uses simple step and direction signals.

Setup is straightforward because the control interface uses simple step and direction signals.

Performance is consistent with built-in safeguards like undervoltage lockout and short-circuit protection. Users benefit from dependable operation, although caution is advised as the module can blow out if miswired. Replacements and spares are available to keep projects on track.

Replacements and spares are available to keep projects on track.

Suitable for hobbyists and professionals working on 3D printers, CNC machines, or robotic applications, the module balances quality and flexibility. It handles complex stepping requirements while maintaining easy integration within existing systems.

Pros

- Supports six different step resolution modes for versatility.

- Robust protection features including thermal and short-circuit safeguards.

- Enhanced heat dissipation thanks to a four-layer copper PCB design.

Cons

- Prone to failure if wired incorrectly, requiring careful installation.

This stepper driver module delivers reliable control and thermal safety in a compact form, making it a practical choice for custom 3D printer and robotics setups seeking precise motion control.

11. HiLetgo 5pcs DRV8825 Stepper Motor Driver Module for 3D Printer

Enhance your 3D printing projects with the HiLetgo DRV8825 Stepper Motor Driver Module. Designed to deliver reliable and efficient performance, this module supports up to 45V supply voltage, making it versatile for various applications.

Its compact design fits easily into most stepper motor driver setups.

Built with a 4-layer, 2 oz copper PCB, the module offers improved heat dissipation, ensuring consistent operation under load. The simple step and direction control interface allows straightforward integration with both

3 V and 5 V systems, making it ideal for a wide range of 3D printers and CNC machines.

Providing excellent build quality, the driver module is crafted to withstand thermal stress thanks to its enhanced copper PCB layers. It supports microstepping up to 1/32 steps, allowing smooth and precise motor control for detailed 3D printing tasks. The compact

94 x 87 x

57-inch size ensures it fits well in space-constrained setups.

Setup is user-friendly, but adjusting the current limit on the potentiometer is essential before operating the motor to avoid overheating. Users benefit from a clear method to set current limits, doubling the voltage measured on the potentiometer to calculate the amps output.

The module performs well on 12V power supplies, offering steady operation at a current limit of 1 amp. It is a cost-effective solution for hobbyists requiring reliable motor control without investing in expensive OEM parts, although the chip is a functional knockoff rather than an original TI component. This makes it suitable for general DIY projects rather than demanding industrial uses.

This makes it suitable for general DIY projects rather than demanding industrial uses.

Pros

- Supports up to 45 V supply voltage for versatile applications

- Enhanced heat dissipation with 4-layer, 2 oz copper PCB

- Compatible with both 3.3 V and 5 V control systems

Cons

- Uses a non-OEM chip which may not meet all original specs

Overall, the HiLetgo DRV8825 Stepper Motor Driver Module provides an effective balance of performance and affordability. It suits users who need precise stepper motor control with easy configuration, delivered in a design that manages heat well for longer use.

While not perfect for industrial-grade tasks, it remains a solid choice for DIY and small-scale 3D printing projects.

12. KEAcvise 5-Pack A4988 Stepper Motor Driver – High-Current Module with

Explore the KEAcvise 5-Pack A4988 Stepper Motor Driver, designed to deliver versatile motion control for various projects. These drivers offer a straightforward interface with reliable performance, making them an efficient choice for CNC and 3D printer applications alike.

Ideal for those needing consistent current management and built-in safety features, these modules integrate advanced protection mechanisms that support stable and secure operation. Included heatsinks help maintain optimal temperature during extended use.

Each stepper driver supports five step resolution modes, from full to sixteenth step. This flexibility allows precise adjustments tailored to project requirements. The drivers operate with a control voltage capability up to 35 V and current levels of ±

The drivers operate with a control voltage capability up to 35 V and current levels of ±2 A, suitable for a broad range of motors.

Adjustable current control with a potentiometer helps customize power outputs to prevent motor overheating. Smart chopping control detects and adapts current decay automatically, enhancing performance efficiency during operation.

Thermal shutdown, under-voltage lockout, and cross-current protection safeguard your electronics and improve device longevity.

Ease of use is boosted with a simple step and direction control interface compatible with common microcontroller boards. These drivers are a practical solution for prototype development as well as compact CNC machines. The five-pack includes heatsinks that keep the units cool under load, reducing the risk of thermal shutdown.

The five-pack includes heatsinks that keep the units cool under load, reducing the risk of thermal shutdown.

Pros

- Supports multiple microstepping resolutions for precise motor control

- Built-in protections including over-temperature and under-voltage lockout

- Adjustable current limits via potentiometer for customized operation

Cons

- Tends to produce more noise compared to newer stepper drivers

Offering dependable features with robust protection, KEAcvise’s A4988 drivers present a cost-effective option for basic 3D printing and CNC control needs. While they may not be the quietest on the market, their reliability and ease of setup make them a solid choice for experimenting and prototyping.

13. WWZMDiB 3 Pcs A4988 Stepper Motor Driver Compatible with for

Experience precise and reliable motor control with the WWZMDiB A4988 Stepper Motor Driver. Designed for smooth integration, it facilitates easy pulse and direction control, eliminating complex setups. Ideal for users seeking a straightforward solution to enhance their 3D printers or CNC devices.

Ideal for users seeking a straightforward solution to enhance their 3D printers or CNC devices.

Its compact QFN28 package fits perfectly in various hardware configurations. With a broad operating voltage range from 8 to 35V, this driver supports a maximum RMS current of 1A, making it versatile for different stepper motors and applications. The built-in 1/16 microstepping capability helps achieve smoother motor operation and reduced vibrations for fine detail work.

The built-in 1/16 microstepping capability helps achieve smoother motor operation and reduced vibrations for fine detail work.

The A4988 module requires minimal configuration, allowing newcomers to start quickly without a steep learning curve. It combines robust build quality with efficient performance, offering consistent results across multiple cycles.

Users can rely on this driver to maintain stability under various load conditions, making it well suited for laser engravers, 3D printers, and other precision devices. Its easy installation and compact size save space while providing reliable motor control. The product balances affordability with quality, making it a practical choice for hobbyists and professionals alike.

Pros

- Simple pulse/direction control with no complex setup required

- Supports 1/16 microstepping for smooth and precise motor movement

- Wide operating voltage range (8-35V) enhances compatibility

Cons

- Maximum RMS current limited to 1A, which may restrict use with higher power motors

Overall, the WWZMDiB A4988 Stepper Motor Driver delivers dependable performance and ease of use at an attractive value. It stands out by combining user-friendly design with solid technical specifications, making it a reliable choice for improving or replacing stepper driver modules.

14. BIGTREETECH TMC2209 V1.3 Stepper Motor Driver, 2.8A UART/DIR/Step Mode Ultra-Silent

Experience whisper-quiet performance with the BIGTREETECH TMC2209 V1.3 Stepper Motor Driver.

Its advanced technology reduces noise and heat for improved efficiency.

Delivering up to 8A peak current, this driver handles demanding motor loads effortlessly. It supports flexible microstepping, contributing to precise control and quieter movements.

Its compatibility with various motherboards makes it a versatile choice for multiple applications.

The BIGTREETECH TMC2209 V1.3 boasts StealthChop2 technology, which ensures ultra-silent motor operation.

The driver supports continuous currents up to 2A and peaks at 8A, catering to most two-phase stepper motors with a voltage range of 75V to 28V.

It achieves smooth positioning through up to 256 microsteps enabled by its microPlyer interpolation unit.

Featuring Stallguard4 locked motor technology, it can perform sensorless homing by detecting motor current shifts. This allows end-of-axis detection without physical limit switches, simplifying printer design. The CoolStep current dynamic control reduces energy consumption by 75%, minimizing heat generation and cooling necessities.

The CoolStep current dynamic control reduces energy consumption by 75%, minimizing heat generation and cooling necessities.

With broad motherboard compatibility including SKR V1.4 Turbo, Octopus Pro, and MKS Gen L, the TMC2209 fits most 3D printer setups. Its versatile modes—STEP/DIR and UART—provide flexible installation options.

Users benefit from smooth, jitter-free operation as the PWM chopper mode avoids missed steps and motor faults, enhancing reliability and print quality.

Pros

- StealthChop2 ensures ultra-quiet motor operation.

- Sensorless homing reduces need for physical limit switches.

- Compatible with a wide range of popular 3D printer motherboards.

Cons

- Extra diagnostic pins may require removal for some CNC shield installations.

The BIGTREETECH TMC2209 V1.3 stands out with quiet, precise motor control and broad compatibility. It provides a reliable upgrade for those seeking smoother, nearly silent stepper motor performance in 3D printing and CNC applications.

It provides a reliable upgrade for those seeking smoother, nearly silent stepper motor performance in 3D printing and CNC applications.

15. Jeanoko DRV8825/A4988 Stable 42 Stepper Motor Driver Expansion Board 3D

Discover enhanced control and reliability with the Jeanoko DRV8825/A4988 Stable 42 Stepper Motor Driver Expansion Board 3D. Designed for smooth and precise operation, this compact expansion board offers flexible drive segment adjustments via an on-board DIP switch. Its terminal power connector allows for effortless power supply connections, delivering convenience in any setup.

Its terminal power connector allows for effortless power supply connections, delivering convenience in any setup.

Engineered specifically for 12V and 24V drive schemes, the board promises compatibility with a range of 42 stepper motors. Whether used in 3D printers or DIY projects, the stable and professional-grade performance provides peace of mind during operation. Small in size but robust in function, this expansion board ensures efficient integration without compromising reliability or stability.

The expansion board features a user-friendly on-board DIP switch to easily tune drive segments, making adjustments straightforward. Its terminal power connector simplifies power connections, eliminating complex wiring hassles.

Compact and highly integrated, the board fits easily into small spaces while maintaining stable performance. It works excellently with 42 stepper motors and is well suited for 3D printing applications and other DIY electronics projects.

Assembly is straightforward, thanks to its modular design that allows for quick driver swaps without soldering.

In addition, customer feedback highlights ease of use in prototyping environments, with straightforward cable connections reducing setup time. The careful design includes protective features like voltage rating considerations to avoid damage. This balance of functionality and durability makes it a practical choice for anyone seeking a dependable stepper motor driver expansion solution.

Pros

- On-board DIP switch offers easy drive segment adjustments without extra tools.

- Terminal power connector simplifies stable and secure wiring of power supply.

- Compact size with stable and professional performance for 3D printer and DIY projects.

Cons

- The board requires careful attention to correct orientation to avoid damage.

The Jeanoko DRV8825/A4988 expansion board delivers reliable stepper motor control with convenient features and solid build quality. Its ease of use and compatibility make it a valuable component for 3D printing setups and custom DIY electronics.

Top 3D Printer Stepper Drivers: Buying Guide 2024

Performance and noise levels

When choosing the best 3d printer stepper driver, paying attention to stepper driver step modes greatly influences the quality and precision of your prints. Microstepping capabilities allow for smoother and more accurate control over the motor movement, enhancing the fine details in your 3d models. Drivers with advanced microstepping options can break down motor steps into smaller increments, which reduces mechanical noise and results in quieter operation.

Noise reduction features are particularly beneficial if you use your 3d printer in shared or quiet spaces, as they help maintain a peaceful working environment. Silent operation is often achieved through integrated technologies within the stepper driver that optimize current flow and motor coil energizing patterns.

Selecting a driver with a good balance between precise step modes and efficient noise reduction will contribute to both improved print results and a more comfortable user experience.

Thermal management and reliability

When selecting a 3d printer stepper driver, paying close attention to how the device manages heat can greatly affect performance and longevity. Effective heat dissipation and cooling solutions such as built-in heat sinks or the option to attach external fans help maintain optimal operating temperatures and prevent overheating during prolonged use.

Incorporating overcurrent and thermal protection features adds an extra layer of safety by automatically reducing power or shutting down the driver to avoid damage under excessive load or high temperatures. Building the driver with durable components and focusing on solid construction enhances its ability to withstand constant electrical and mechanical stress, thereby improving reliability over time. Considering these aspects can lead to a more consistent and stable printing experience while also reducing the likelihood of hardware failure.

Compatibility with 3d printer models

When selecting a stepper driver for a 3D printer, matching its specifications with the requirements of your printer’s mainboard is fundamental to achieving smooth operation. The voltage and current capacities of the driver must align with what your stepper motors and controller board can handle, preventing overheating or underperformance.

Considering the common variations among mainboards, examining the physical connector layout alongside electrical properties helps avoid mismatched parts that could otherwise cause wiring complications or operational issues. Stepper drivers designed for various current ratings allow for customization depending on the motor’s torque needs and precision, making it beneficial to check these values against the printer’s specifications.

Thoughtful evaluation of these factors ensures that the selected driver integrates seamlessly, delivering consistent and accurate motion control tailored to your 3D printing tasks.

Understanding stepper drivers for 3d printers

Stepper drivers play a fundamental role in 3D printers by controlling the movement of the stepper motors, which are responsible for the precise positioning of the print head and build platform. Various types of these drivers exist, including models that offer different modes of microstepping, current control, and thermal protection.

When evaluating options, key features to focus on include compatibility with your printer’s electronics, the current rating each driver can handle, and features like adjustable current settings and quiet operation. Typical use cases involve ensuring smooth and accurate motor movement, reducing noise during printing, and protecting the motors from overheating. Spending time understanding the specifications related to voltage requirements and step resolution will help in making a choice suitable for specific printer models and desired printing quality.

Additionally, some drivers come with advanced features such as stall detection and sensorless homing, which enhance the reliability and ease of use of a 3D printer during operation.

Ease of installation and configuration

Choosing a suitable 3d printer stepper driver involves paying attention to firmware support and configuration options because compatibility with your printer’s control board firmware allows for smoother integration and performance tuning. Software compatibility and tuning flexibility play an important role as well, since drivers that work seamlessly with various 3d printing software enable you to fine-tune motor behavior, improving print quality and reducing noise.

Reliable documentation and user support availability add significant value by providing clear instructions and troubleshooting assistance, which is especially helpful for newcomers seeking to optimize their printer setup without challenges. Balancing these factors can lead to a more streamlined installation process while offering the adaptability needed for different projects and printer models.

Price and value for money

Choosing between budget and premium drivers often depends on the intended use and the level of performance you desire. Budget options can be attractive for those starting out or handling simpler projects, offering basic functionality at a lower cost.

Premium drivers, on the other hand, tend to provide enhanced features such as smoother motor control, quieter operation, and better thermal management, which can improve print quality and machine longevity. When making a purchase, it’s wise to consider the warranty and customer service support offered by the manufacturer, as responsive service can save time and money if issues arise. Long-term reliability plays a significant role in overall investment since a durable driver reduces the need for replacements and maintenance, ultimately providing more consistent performance over time.

Balancing initial cost with durability and support helps in making a choice that aligns with both budget constraints and long-term satisfaction.

Frquently Asked Questions

How Do Tmc22And Tmc22Stepper Drivers Compare For Printing Applications?

The TMC22 and TMC22stepper drivers are both designed for precise motor control, but they differ in features suited for printing applications. The TMC22 offers reliable current control and quiet operation, making it a solid choice for basic 3D printing tasks. It provides smooth motion but lacks some advanced functionalities. On the other hand, the TMC22stepper driver enhances printing performance with improved microstepping and smarter thermal management. This leads to quieter, more accurate prints and better motor protection during extended use, making it preferable for high-quality or professional-grade 3D printers.

Can Upgrading To A Better Stepper Driver Reduce Noise And Improve The Precision Of A Printer?

Upgrading to a better stepper driver can significantly reduce noise in a printer. Advanced drivers often use smoother current modulation techniques like microstepping and spreadCycle or stealthChop, which minimize the vibrations and audible noise produced by the stepper motors. This results in quieter operation, making the printer more suitable for home or office environments. In addition to noise reduction, improved stepper drivers enhance precision by providing more accurate control of motor movements. They enable finer microstepping and better current regulation, which leads to smoother motion and higher positional accuracy. Consequently, print quality can improve with sharper details and fewer artifacts.

How Do Different Stepper Drivers Affect The Print Quality Of A Printer?

Different stepper drivers influence a 3D printer’s print quality by controlling the precision and smoothness of the motor movements. High-quality drivers, like Trinamic or TMC series, provide quieter operation and finer microstepping, resulting in smoother and more accurate layer deposition. Conversely, basic or low-quality drivers may cause vibrations, missed steps, and increased noise, leading to rougher surfaces and lower detail resolution. Additionally, advanced stepper drivers often include features like current control and thermal protection, which help maintain consistent motor performance. This stability reduces print defects such as layer shifting and ghosting, ultimately enhancing the overall print quality and reliability of the printer.

What Features Should I Look For When Choosing A Stepper Driver For My Printer?

When choosing a stepper driver for your printer, prioritize key features such as microstepping capability, current rating, and thermal management. Microstepping allows smoother and quieter motor operation with higher precision, while the current rating should match your stepper motor’s requirements to ensure reliable performance without overheating. Additionally, consider the driver’s compatibility with your printer’s control board and ease of integration. Features like adjustable current control, built-in protection circuits, and silent operation modes can enhance printing quality and longevity. Selecting a driver with good community support and documentation is also beneficial.

What Are The Top-Rated Stepper Drivers For Printers In Terms Of Performance And Reliability?

Top-rated stepper drivers for printers, known for their performance and reliability, include the Trinamic TMC2209, TMC2130, and DRV8825. The Trinamic TMC series is popular for its quiet operation, precise current control, and advanced features like sensorless homing, making them ideal for 3D printers. The TMC2209 is especially favored for its balance of noise reduction and smooth motion. The DRV8825 is another reliable choice, noted for its robustness and ease of use in various printer setups. It offers good torque and high microstepping resolution, making it a versatile and cost-effective option for many printer enthusiasts.

Conclusion

Choosing the best 3d printer stepper driver involves balancing factors such as smooth motor control, heat management, noise levels, and compatibility with your printer. While some drivers offer advanced features like silent operation and thermal protection, they may require additional cooling or more precise setup. These drivers suit those seeking quieter and more efficient printing experiences, especially for complex or high-speed projects.

These drivers suit those seeking quieter and more efficient printing experiences, especially for complex or high-speed projects. However, beginners might find certain models less straightforward to install or tune. Ultimately, the best 3d printer stepper driver depends on your specific needs and technical comfort.

By weighing performance benefits against installation complexity, buyers can confidently select a stepper driver that enhances print quality and reliability without compromising ease of use.