Finding the right 3D printer for jewelry casting can be a challenge, especially when precision and detail are so important. Many printers struggle to deliver the fine resolution needed to create intricate designs, which is why choosing the best 3d printer for jewelry casting matters.

It offers a blend of reliable performance and user-friendly features that make creating detailed wax models or cast patterns easier and more efficient. In this review, we will explore the key features, pros, and cons of the best 3d printer for jewelry casting.

You will learn how it handles delicate designs, what makes it a worthwhile investment, and whether it fits different skill levels and budget ranges.

| Image | Name | Our Rating | Price |

|---|---|---|---|

|

Siraya Tech Cast 3D Printer Resin Easier...

|

|

|

|

Siraya Tech Cast 3D Printer Resin Easier...

|

|

|

|

3DMaterials SuperCast 8K 3D Printer Resi...

|

|

Unlock Precision and Detail: Top Choices for Crafting Exquisite Jewelry Models

| Image | Product | Price |

|---|---|---|

Our Top Picks 1  | Siraya Tech Cast 3D Printer Resin Easier to Burn and | Check Price |

Our Top Picks 2  | Siraya Tech Cast 3D Printer Resin Easier to Burn and | Check Price |

Our Top Picks 3  | SuperCast 8K 3D Printer Resin Wax Filled for Ultrafine Filigree, | Check Price |

1. Siraya Tech Cast 3D Printer Resin Easier to Burn and

Siraya Tech Cast 3D Printer Resin stands out as a reliable solution for jewelry casting applications. Its unique wax-based formula ensures a cleaner and easier burnout process, making it highly suitable for intricate and thicker designs such as bracelets and metal parts.

Designed with both beginners and seasoned users in mind, this resin delivers high-resolution prints with remarkable surface quality. The brilliant blue hue highlights fine details and smooth finishes, elevating the overall quality of your cast models.

What sets this resin apart is its exceptional printability without demanding strict environmental conditions. Unlike other castable resins, it performs well without requiring additives or ultra-dry setups.

This makes it accessible to a wide range of 3D printer users.

The wax content aids in clean burnouts, minimizing ash residues even in dense objects. Models crafted with this resin exhibit fine details and ultra-fine structural features due to its softer composition and impressive resolution.

Ideal not only for jewelry casting but also for dental applications and metal parts, the resin works compatibly with most LCD, DLP, and SLA printers. High surface gloss and vivid true blue color provide excellent visual feedback during post-processing, making finishing steps more straightforward.

Pros

- Wax-infused formula allows cleaner, easier burnout with minimal ash.

- High resolution captures ultra-fine details and complex structures.

- No need for overly dry environments or special additives during printing.

Cons

- Models can be fragile before proper post-curing, requiring careful handling.

Offering precise prints with simplified processing, Siraya Tech Cast resin proves to be an excellent choice for producing quality jewelry prototypes and metal parts. Its balance of usability and performance makes it a competitive option among castable resins available today.

2. Siraya Tech Cast 3D Printer Resin Easier to Burn and

Discover a resin crafted especially for jewelry casting that combines ease of use with exceptional print quality. The Siraya Tech Cast 3D Printer Resin offers a smooth printing experience and outstanding detail, making it a preferred choice for precise casting projects.

This castable resin stands out with its clean burn properties and excellent adhesion, ensuring your models capture every tiny detail. It simplifies the casting process with less ash and residue, ideal for intricate designs and thicker pieces.

Siraya Tech Cast resin delivers an impressive balance between high resolution and user-friendly handling. Designed with wax content, it burns out cleanly, leaving minimal ash compared to traditional castable resins. This makes it highly suitable for printing dense items like bracelets and larger metal parts without compromising detail.

Printing with this resin requires no special additives or extremely dry conditions, allowing both beginners and professionals to achieve sharp results quickly. The resin features a bright blue tint that enhances surface gloss and print clarity, adding a professional finish to cast jewelry and dental models alike.

Compatible with most LCD, DLP, and SLA 3D printers, the Siraya Tech Cast resin caters to a range of applications beyond jewelry, including medals and coins. Its softer texture aids in capturing ultra-fine features, delivering smooth surfaces and complex geometry with ease.

Pros

- Burns out cleanly with minimal ash, ideal for thick and detailed designs

- Easy to print with no special additives or strict environmental needs

- High resolution with smooth surface finish perfect for precise castings

Cons

- Printed models are fragile before post curing and require careful handling

Overall, Siraya Tech Cast resin offers reliable performance for detailed jewelry and metal casting projects. Its clean burn properties and ease of use make it a practical choice for users who prioritize precision and workflow simplicity over complex handling requirements.

3. SuperCast 8K 3D Printer Resin Wax Filled for Ultrafine Filigree,

Discover the innovative SuperCast 8K 3D Printer Resin Wax Filled specially designed for intricate jewelry casting. Its unique wax-filled formulation supports ultra-fine filigree designs, making delicate creations easier to achieve.

Boasting 8K resolution, the resin allows fast printing at 22-micron detail without sacrificing quality. Its compatibility with all LCD printers and low burning temperature improve workflow efficiency. This resin makes creating high-quality, ash-free castings straightforward and reliable.

SuperCast resin excels with its wax-filled strength, offering stiffness that maintains delicate structures through the printing and casting processes. The low viscosity formula supports smooth layering and high-speed printing, producing ultra-fine, detailed models.

Thanks to its unique photosensitization technology, the resin works seamlessly with most standard and mono LCD 3D printers, expanding its usability.

No post-curing is needed, which helps prevent incomplete burnout, a common problem with other resins. The resin burns out cleanly at lower temperatures, leaving no ash or residue behind, essential for precision jewelry casting. Users have praised its reliable burnout using simple jewelry torches rather than expensive kilns or ovens.

Users have praised its reliable burnout using simple jewelry torches rather than expensive kilns or ovens.

The resin’s dimensional stability and strength make it ideal for professionals and hobbyists focusing on detailed jewelry pieces. Its robust performance coupled with easy handling saves time and effort during production. Overall, it offers an excellent balance of precision, durability, and convenience for creating fine casting patterns.

Pros

- High-resolution 8K printing with 22 micron detail for intricate designs

- Wax-filled resin ensures strong, stiff prints ideal for fine filigree

- Compatible with all regular and mono LCD 3D printers

- No post-curing process required, simplifying workflow

- Burns out completely at low temperatures with no ash residue

Cons

- Limited information on color options available

The SuperCast 8K resin stands out as a reliable choice for jewelry casting with detailed requirements. Its high precision, clean burnout, and broad printer compatibility make it a valuable asset for anyone producing delicate castings. The ease of use and excellent printing results contribute to a smooth creative process.

4. Siraya Tech Cast 3D Printer Resin Easy to Print Use

Deliver exceptional precision for jewelry casting projects with Siraya Tech Cast 3D Printer Resin. Designed for ease of use, this resin adapts well to different printing environments without special additives. Its unique purple hue not only adds aesthetic appeal but also highlights fine details accurately.

Crafted for jewelers and makers of small metal parts, the resin balances quality with convenience. It supports fast printing speeds, smooth surfaces, and reliable burnout processes to meet demanding creative needs.

Siraya Tech Cast resin offers a versatile solution for detailed 3D printing. It adheres well to print plates and requires no stringent environmental controls, simplifying the printing setup. The material’s wax content increases burnout efficiency, making it ideal for casting small, intricate metal components.

The material’s wax content increases burnout efficiency, making it ideal for casting small, intricate metal components.

The resin produces highly detailed results with a smooth finish, capturing delicate designs accurately. It performs across various LCD and DLP printers, including those with 8K capability, expanding its usability. Users appreciate its relatively straightforward printing process and quick curing times compared to other castable resins.

While the resin delivers excellent definition, achieving optimal results demands precise settings and post-processing care. It works best for professionals or hobbyists involved in jewelry and dental applications requiring detailed, small-scale models.

Despite some challenges in cleanup and curing, it remains a cost-effective option with consistent output and broad compatibility.

Pros

- Excellent high-resolution prints with smooth surface finish

- Improved burnout thanks to embedded wax content for casting

- Compatible with most LCD and DLP 3D printers, including 8K models

Cons

- Requires careful tuning of settings and meticulous post-processing

For creators aiming to produce finely detailed jewelry or small metal parts, this resin offers precision and adaptability. While demanding attention to process details, it delivers rewarding results that balance quality and printing ease.

Considering its compatibility and the quality of finished products, it stands as a strong candidate among castable 3D printer resins.

5. Castable 3D Printer Resin, High-Temperature Resistance Resin for Jewelry and

Experience precision and reliability with Castable 3D Printer Resin, specially designed for jewelry casting. This high-temperature resistance resin ensures detailed, flawless prints, helping you create intricate rings, pendants, and custom jewelry with ease.

Engineered for smooth operation, it offers exceptional flow and quick curing times. Perfect for professionals and hobbyists alike, it supports a streamlined workflow and top-quality results every time.

Achieve sharp, accurate detail reproduction with a resin formulated to capture even the smallest features. Its ultra-low ash content minimizes residue during burnout, preserving the quality and surface finish of your castings.

Compatible with most LCD, DLP, and MSLA resin printers, it suits a wide range of printing platforms. Setup is straightforward, enabling smooth prints with minimal failed attempts. The resin also emits a mild odor and requires a slightly longer wash time, which is a small trade-off for its outstanding precision and finish quality.

The resin also emits a mild odor and requires a slightly longer wash time, which is a small trade-off for its outstanding precision and finish quality.

Designed to meet demanding professional standards, it offers excellent value by reducing reprints and waste. Whether in a small studio or a commercial environment, this resin supports complex design needs with consistent performance and ease of use.

Pros

- Exceptional detail reproduction capturing intricate jewelry designs

- Ultra-low ash content for clean, flawless castings

- Broad compatibility with most resin 3D printers (LCD, DLP, MSLA)

Cons

- Requires a bit longer washing time to achieve the best finish

This castable resin combines precision, ease of use, and professional-grade results, making it an excellent choice for jewelry makers seeking reliable performance. Its quality and versatility allow for efficient production across a variety of designs and printers.

6. SuperCast 8K 3D Printer Resin Wax Filled for Ultrafine Filigree,

The SuperCast 8K 3D Printer Resin Wax Filled offers remarkable precision and ease for jewelry casting projects. Designed specifically to handle intricate filigree details, it elevates the quality of your 3D printed wax models. This resin combines strength and finesse, ensuring delicate designs come out flawlessly every time.

This resin combines strength and finesse, ensuring delicate designs come out flawlessly every time.

With its unique formula, SuperCast eliminates the need for post-curing, simplifying the workflow. The low burning temperature allows smooth burnout without residues, which is critical for flawless casting results.

It adapts seamlessly to most LCD and monochrome printers, making it a versatile addition to any jewelry maker’s toolkit.

SuperCast resin boasts an ultra-high 8K resolution capability with a stunning 22-micron layer precision. Its low viscosity supports fast printing speeds without sacrificing detail or smoothness.

Significantly, there is no need for post-curing as it burns out completely at a lower temperature, leaving no ash behind. This feature reduces the chances of casting defects and shortens production time.

Compatibility extends across virtually all regular and mono LCD printers thanks to its advanced photosensitization technology.

Weighing just 1 pounds with compact dimensions, this resin is convenient to handle and store. Jewelry designers and small manufacturers will find it particularly suited for producing precise wax patterns without complicated setups.

Its ease of use and reliability make it a strong contender among similar casting resins available on the market today.

Pros

- Wax-filled resin providing sturdy and stiff prints for intricate designs

- Burns out cleanly at low temperatures with no ash residue

- Compatible with all regular and mono LCD 3D printers due to unique photosensitization

Cons

- Post-curing is not recommended and may cause incomplete burnout

SuperCast 8K Resin Wax Filled stands out by combining ultrafine detail with easy burnout and broad printer compatibility. Its specialized formula simplifies casting preparation, making it a reliable choice for creating high-precision jewelry wax models.

7. Formlabs True Cast Resin for 3D Printers – High Precision

Discover unparalleled precision and reliability with the Formlabs True Cast Resin for 3D printers. Specially crafted for jewelry casting, this resin delivers consistently detailed, smooth, and highly accurate prints.

It elevates the quality of your designs, helping create flawless casts every time.

Ideal for complex patterns and heavier pieces, the resin supports intricate and demanding projects with ease. Its formulation ensures clean burnouts and minimal residue, making it an excellent choice for artisans seeking dependable results.

The Formlabs True Cast Resin offers impeccable print clarity, capturing fine details with crisp edges and smooth finishes. It’s engineered for low expansion, which means printed parts retain their shape during the casting process without wax migration.

The resin produces ashes with only 03% content, ensuring clean burnout that integrates seamlessly with existing investment workflows. It handles parts up to 5mm thickness, accommodating both delicate jewelry patterns and robust engineering components.

Users can trust its consistent quality, which reduces rework and improves efficiency.

Built by Formlabs, a reputable manufacturer in 3D printing, the product balances performance with ease of use. Its compatibility with Formlabs printers allows smooth workflow and reliable results.

This resin suits professionals and hobbyists looking for precision and versatility in casting, making it a standout choice among resin options.

Pros

- High precision with crisp features and smooth surfaces

- Low expansion and no wax residue for reliable casting

- Clean burnout with minimal ash content and low shrinkage

Cons

- Best suited for use with Formlabs 3D printers only

Formlabs True Cast Resin combines exceptional detail with dependable performance, making it a valuable addition to any jewelry casting workflow. Its reliability and quality results make it a compelling option for anyone focused on precision casting tasks.

8. Siraya Tech Sculpt High-Temp Resistant 3D Printer Resin – Up

Siraya Tech Sculpt High-Temp Resistant 3D Printer Resin offers exceptional heat tolerance reaching up to 250°C. Designed to handle demanding production processes, it combines durability and sharp detail, ideal for specialized industrial and creative projects.

Its ultra white color enhances model aesthetics while minimizing post-print work. This resin is perfect for users needing precision and resistance in high-temperature environments.

Sculpt resin stands out for its impressive resistance to heat, allowing it to perform reliably in prototype parts, vulcanized rubber molding, and injection mold applications. Its minimal shrinkage ensures accurate prints with a smooth surface finish. The ceramic-filled formula provides rigidity and low water absorption, resulting in models that exhibit both strength and fine detail.

Compatible with high-power DLP and LCD printers, including Moonray, it suits small-batch production requiring consistently high-quality results. While it demands precise bed leveling due to its opacity, careful calibration solves adhesion challenges. Post-printing is simplified as supports break away cleanly, enhancing workflow efficiency.

Besides its standalone advantages, this resin can be blended with others to improve heat deflection temperature, offering enhanced performance tailored to specific needs. Users who require heat, chemical, and wear resistance in their prints will find Sculpt resin especially beneficial for creating durable, high-resolution models.

Pros

- Exceptional heat resistance up to 250°C for demanding applications

- Ultra white finish delivers smooth surfaces with high resolution

- Low shrinkage maintains dimensional accuracy and detail

Cons

- Requires precise bed leveling due to resin opacity and brittleness

Siraya Tech Sculpt resin excels where high heat tolerance and detail are essential. Its ability to enhance other resin blends adds versatility, making it a reliable choice for demanding 3D printing projects focused on durability and precision.

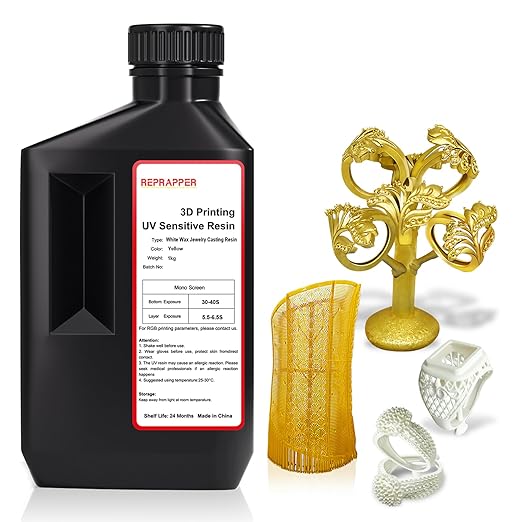

9. Reprapper White-Wax Casting 3D Printer Resin, Castable LCD UV-Curing 1kg

Achieve flawless results in jewelry casting with the Reprapper White-Wax Casting 3D Printer Resin. Designed for precision and reliability, this resin delivers smooth surfaces and crisp detail to elevate your creative projects. Its unique formulation supports efficient casting workflows, making it a trusted material for professional applications.

Its unique formulation supports efficient casting workflows, making it a trusted material for professional applications.

Combining ease of use with advanced performance, this resin simplifies the burn-out process and maintains dimensional accuracy. Whether for custom pieces or intricate designs, it adapts well to various 3D printers, ensuring consistent quality for jewelry makers seeking dependable casting results.

Reprapper’s White-Wax Casting Resin stands out by providing excellent casting outcomes with a notably smooth finish. Its special wax-infused recipe helps produce a thin film that enhances metal flow during casting.

This feature minimizes defects and supports a clean melt, streamlining the creation of detailed jewelry components.

Burn-out of the resin is straightforward and fast, featuring a steady temperature ramp of 33℃ per minute without producing ash residue or noise. This ease reduces risk during the burnout phase and improves overall efficiency in the foundry process.

Additionally, the resin exhibits remarkable dimensional stability when exposed to UV light, keeping printed models true to size throughout curing and burnout stages.

Compatibility covers a wide range of 405nm LCD and DLP printers such as B9C, Phrozen, Elegoo, and Anycubic models. The resin starts with a yellow tint but turns pure white after washing and post-curing, making flaw detection easier before proceeding to casting. This functionality supports quality control while enhancing the value offered to creators and small businesses focused on jewelry production.

Pros

- Produces smooth surfaces with professional-grade casting quality

- Fast and clean burn-out process without ash or bubbles

- Highly compatible with most 405nm LCD and DLP 3D printers

Cons

- Initial yellow color requires washing and curing to reach pure white

Offering a combination of precision, ease of use, and compatibility, the Reprapper White-Wax Casting Resin is an excellent choice for jewelry casters aiming for flawless prints. It enhances the workflow by simplifying burnout and improving surface quality, ultimately saving time and resources for small-scale professionals and hobbyists alike.

10. Cast100P Castable 3D Printer Resin, 405nm UV Curing High Precision

Precision and reliability are indispensable when creating jewelry. Cast100P Castable 3D Printer Resin offers ultra-high accuracy tailored specifically for jewelry casting.

Designed for compatibility with 405nm UV curing printers, this resin delivers outstanding print quality and smooth post-processing. It helps artisans and designers produce refined, burnable models that translate perfectly to final casts.

The Cast100P resin is formulated to maintain exceptional dimensional stability during the burn-in casting stage. With a low thermal expansion coefficient, it prevents distortion and guarantees precise reproduction of intricate patterns after casting.

008% residual ash left behind.

Its upgraded composition reduces odor and simplifies cleaning, creating a more comfortable environment throughout printing and post-print handling. This resin supports seamless washes, which helps preserve the fine details crucial in jewelry design.

Crafted for jewelry designers and small-scale manufacturers, the Cast100P resin balances ease of use with high-performance results. It offers a cost-effective option compared to similar castable resins without compromising precision or reliability.

Its sturdy packaging and user-friendly instructions further enhance the overall experience.

Pros

- Exceptional dimensional accuracy reduces model deformation during casting.

- Very low ash content ensures clean burnout and detailed final casts.

- Low odor and easy-to-wash formula improves user comfort and workflow.

Cons

- Best results require adherence to recommended printing parameters for each printer model.

Cast100P provides a reliable, specialized resin solution for jewelry 3D printing. Its precision, burnability, and ease of use make it a strong choice for anyone crafting detailed cast models.

This resin stands out among other castable materials, especially for those focused on clean and accurate jewelry reproductions.

11. Antinsky Castable Jewellery Smart Resin for DLP LCD UV-Curing 405nm

Antinsky Castable Jewellery Smart Resin is crafted specifically for precision and reliability in jewelry casting. It offers detailed and strong prints that meet the demands of intricate design work.

This resin supports seamless curing with optimal viscosity and density levels, providing smooth printing experiences. Whether creating prototypes or final pieces, it balances performance with ease of use for professionals and hobbyists alike.

Offering a viscosity range of 70 to 180 mPa·s and density between 05 and 25 g/cm³, this resin handles fine details without sacrificing material strength.

25 g/cm³, this resin handles fine details without sacrificing material strength. Its tensile strength at 88 MPa and an elongation at yield point of

34% guarantee durability during casting processes. The shore hardness rating of 58 to 68D supports elasticity while maintaining toughness.

Printing parameters include layer thickness from 02 to

05 mm and exposure times from 8 to 12 seconds, allowing precise control over print quality. The resin’s absorption band of 385 to 410 nm adapts well to most 405 nm UV light sources, enhancing consistency during curing stages.

Users find it easy to handle with straightforward post-processing steps. Despite some challenges with residue during burnout, the resin largely burns out cleanly without expansion or breakage, preserving detail integrity.

This makes it well-suited for jewelers focusing on quality and precision in small batch production or custom designs.

Pros

- Exceptional detail and dimensional accuracy for jewelry casting

- Strong mechanical properties including tensile and bending strength

- Compatible with common UV-curing systems for versatile use

Cons

- Residue left after burnout can affect investment interaction and requires troubleshooting

The Antinsky Castable Jewellery Smart Resin is a dependable choice for crafting detailed jewelry pieces with strength and accuracy. It suits those seeking reliable performance in UV-curing 3D printing and offers a good balance between print quality and ease of use.

Compared to other resins, its mechanical properties and smooth printing process make it a valuable option for specialized applications.

12. Antinsky W80 Castable Jewellery Resin for DLP LCD UV-Curing 405nm

Crafted for precision and clarity, the Antinsky W80 Castable Jewellery Resin stands out as a reliable choice for detailed jewelry printing. Designed to work seamlessly with DLP, LCD, and UV-curing 405nm 3D printers, it offers exceptional performance for detailed casting models.

Its unique white hue enhances visibility of fine details, making it easier to evaluate the model before casting. This resin is engineered to burn cleanly, reducing waste and simplifying the forging process for thicker and intricate pieces.

Antinsky W80 resin delivers ultra-high resolution printing suitable for complex jewelry designs like bracelets, pendants, coins, and medals. The white color allows users to easily inspect models, ensuring accuracy and reducing resource waste before investing in casting. It contains wax that facilitates quick, ash-free burnout, ideal for thicker models which typically require more careful processing.

It contains wax that facilitates quick, ash-free burnout, ideal for thicker models which typically require more careful processing.

Its low thermal expansion minimizes deformation during the burn-out phase, preserving the precision of the printed piece. Compatible with most LCD, DLP, and SLA printers, the resin supports a wide range of jewelry casting applications.

The included instructions for soaking and curing help achieve optimal white model results, ensuring long-lasting durability and dimensional stability.

Reliable for both hobbyists and professionals looking for quality details in jewelry casting, this resin offers clear workflow advantages. It strikes a good balance between performance and ease of use, simplifying post-print processing while maintaining exceptional print fidelity.

Pros

- High-resolution white resin highlights intricate details clearly.

- Wax composition enables fast, ash-free burnout for thicker models.

- Low thermal expansion ensures minimal model deformation during casting.

Cons

- Users seeking flawless prints may experience mixed results with this resin.

The Antinsky W80 Castable Jewellery Resin provides a specialized solution for crafting detailed jewelry pieces with precision. Its unique features enhance both print clarity and post-processing, offering valuable support for designers focused on accuracy and efficiency in casting.

13. FLASHFORGE Adventurer 5M 3D Printer with Fully Auto Leveling, Max

Discover the FLASHFORGE Adventurer 5M 3D Printer, designed for smooth, reliable printing with minimal effort. Its automatic leveling and fast printing capabilities offer consistency and speed without complicated setup.

Craft your ideas effortlessly while enjoying remote monitoring and adaptable features. This printer is an excellent tool for precise prototyping and creative projects alike.

Equipped with one-click automatic bed leveling, the Adventurer 5M removes guesswork from the process. This guarantees a perfectly balanced print bed for clean first layers and strong adhesion every time. The CoreXY motion system enhances speed with travel up to 600mm/s and accelerations reaching 20000mm/s², cutting production times drastically.

The CoreXY motion system enhances speed with travel up to 600mm/s and accelerations reaching 20000mm/s², cutting production times drastically.

Its heated nozzle reaches 200°C fast and changes in just three seconds, boosting overall printing efficiency. The dual-sided PEI platform makes removing prints simple and supports diverse project demands.

25 to 8mm, offering customization for different print resolutions.

Real-time monitoring via the Flash Maker app enables remote control and insights into print status. Vibration compensation and dual-fan nozzles contribute to detailed, high-quality results. While primarily suited for professionals and hobbyists seeking reliability, this printer adapts well to various skill levels and applications.

While primarily suited for professionals and hobbyists seeking reliability, this printer adapts well to various skill levels and applications.

Pros

- Automatic bed leveling simplifies preparation and enhances adhesion.

- High-speed CoreXY mechanism shortens print times significantly.

- Remote monitoring permits convenient control through a mobile app.

Cons

- Some users report filament feeding interruptions affecting print consistency.

The FLASHFORGE Adventurer 5M balances precision, speed, and user-friendly features effectively. While occasional filament issues have been noted, its advanced design and customer support make it a valuable choice for those prioritizing efficiency and quality in 3D printing tasks.

14. Jewelry Casting 3D Printer Resin, Red 500g

Delivering precision and reliability, the Jewelry Casting 3D Printer Resin in vibrant red is designed specifically for crafting detailed jewelry pieces. It promises exceptional quality and smooth finishes, making it a preferred choice for jewelry professionals and hobbyists alike.

This resin stands out for its consistency and accuracy, tailored to meet the demanding requirements of casting applications. Ideal for producing fine, intricate designs, it complements a range of 3D printers designed for jewelry making.

Formulated by FUNCRECOL, this red resin ensures sharp detailing with minimal post-processing efforts. Its composition supports high-resolution outputs for flawless layering and surface smoothness on each print.

The 500g bottle provides ample material to pursue multiple projects without frequent refills.

The resin’s packaging is compact, measuring 5 x

9 x 9 inches, and weighs just 2 pounds.

Such size allows convenient storage and use without clutter. Users benefit from its balance between fluidity and curing time, delivering efficiency throughout the printing process.

Durability is another highlight, minimizing the risk of print warping or cracking during casting. This resin is particularly suited for professionals focused on jewelry casting but accessible enough for those entering the field. Combining quality with ease of use, it fits various printer models designed for precise jewelry fabrication.

Pros

- Produces high-resolution and smooth jewelry models

- Consistent curing with minimal post-processing required

- Compact and lightweight packaging for easy handling

Cons

- May require calibration for some 3D printer models

Offering excellent detail and reliable performance, this red resin is a valuable choice for jewelry casting needs. It balances precision, ease of use, and manufacturing quality, making it a strong contender in its category.

15. Antinsky Castable Dental Resin for DLP LCD UV-Curing Resin 3d

Antinsky Castable Dental Resin offers an exceptional solution designed for jewelry casting with precision and reliability. Its unique formulation supports flawless wax pattern printing, meeting high standards for detail and dimensional accuracy.

Engineered to provide clean combustion and excellent material performance, this resin complements various paraffin casting techniques. Ideal for professionals seeking consistent and high-quality casting outcomes.

Crafted with 40% wax content, the resin ensures complete combustion leaving no ash behind. This feature supports smooth burnout processes, which is critical for producing flawless jewelry pieces. The low expansion rate also helps maintain pattern integrity during casting.

Antinsky resin achieves sharp details on printed patterns coupled with impressive hardness levels. These characteristics enable precise molds that capture intricate designs accurately. Its compatibility with different paraffin casting environments adds versatility to its use.

Its compatibility with different paraffin casting environments adds versatility to its use.

The formula works well with premium gypsum materials, enhancing the casting wrap effect and contributing to superior casting results. Users benefit from its adaptability across various 3D printers supporting DLP, LCD, and UV curing technologies.

Evaluated for performance and user-friendliness, this resin balances quality and practical application. It suits jewelers focusing on detailed, durable castings with an emphasis on efficiency and repeatability. Overall, it delivers reliable performance aligned with professional jewelry manufacturing needs.

Pros

- Ensures complete combustion with no ash residue

- Produces highly detailed and hard wax patterns

- Compatible with multiple casting methods and gypsum types

Cons

- Limited to specific 3D printer technologies for optimal results

Offering a balance of precision, compatibility, and clean burnout, Antinsky Castable Dental Resin stands out for jewelry casting applications. It delivers dependable, detailed prints that simplify the casting process, making it a strong choice for professionals focused on quality outcomes.

Ultimate Guide to Choosing the Best 3D Printer for Jewelry Casting Mastery

User interface and software

When selecting a 3D printer for jewelry casting, the ease of use and the learning curve play significant roles in deciding how quickly one can begin producing detailed pieces. Printers that come with intuitive controls and clear instructions help smooth the initial setup and daily operation.

Moreover, having multiple connectivity options such as USB and WiFi allows for greater flexibility in transferring files and integrating the printer into existing workflows, whether working from a desktop or remotely. Together, these factors contribute to a more efficient and enjoyable printing experience, especially for those new to this art form.

Printer reliability and maintenance

Choosing a 3D printer for jewelry casting involves paying attention to how often maintenance is required and how simple those tasks are to perform. Machines that need frequent upkeep or complex servicing can slow down your workflow and increase costs over time. It is helpful to pick models that offer readily available replacement parts to avoid long waiting periods and keep your projects on schedule.

Being backed by responsive customer support and a solid warranty also adds peace of mind by providing assistance when technical issues arise or if repairs are necessary. Prioritizing these factors helps maintain smooth operation and protects your investment while ensuring consistent output quality for intricate jewelry designs.

Build volume and print size

When selecting the best 3d printer for jewelry casting, it is helpful to pay attention to the size of the build area as jewelry pieces typically require a compact space that supports fine detail work. Jewelry often involves small and intricate designs, so a printer capable of finely tuned precision helps capture delicate features and subtle textures, making the final cast more accurate and appealing. The ability to print several items side by side can improve efficiency, especially for business purposes or designing collections, allowing multiple pieces to be produced in one session without compromising quality.

The ability to print several items side by side can improve efficiency, especially for business purposes or designing collections, allowing multiple pieces to be produced in one session without compromising quality. Being mindful of printers that manage small components well can aid in reducing errors and finishing work, which contributes to smoother production and higher-quality results in jewelry creation.

Print technology and resolution

When choosing the best 3d printer for jewelry casting, understanding the differences between the main technologies can greatly influence the quality of your pieces. Each type like SLA, DLP, and LCD offers unique strengths that affect how finely details are rendered.

SLA typically uses a laser to cure resin with high precision, providing smooth surfaces and delicate detail, while DLP and LCD employ light sources that cure entire layers at once, which can speed up printing but sometimes with slight variations in sharpness. The significance of layer height and XY resolution cannot be overstated, as these factors determine how thin each resin layer is and how accurately the printer can reproduce details horizontally. Smaller layer heights and finer resolutions result in smoother finishes and crisper textures, which is especially beneficial for delicate jewelry designs where subtle features matter.

Paying attention to these aspects ensures that the final castings capture intricate patterns and achieve a polished look straight from the print, reducing the need for extensive post-processing and improving the overall workflow in jewelry making.

Material compatibility

When choosing a 3D printer suited for jewelry casting, paying close attention to material compatibility will greatly impact the quality and feasibility of your projects. A good printer should support a variety of resins specifically formulated for jewelry work, especially those that can burn out cleanly without leaving ash or residue, making them ideal for casting processes.

The availability of castable resin options in the market can vary, so finding a printer that not only works well with proprietary resins but also allows flexibility for third-party materials can offer greater versatility and cost-effectiveness. This compatibility extends beyond resin types to include different formulations such as wax-like resins that simplify creating intricate designs. By ensuring the printer is compatible with commonly used castable resins and other materials preferred by jewelry makers, users can achieve smooth, highly detailed prints that translate well into the final metal pieces.

Choosing a device that accommodates a range of castable resin options while maintaining compatibility with third-party suppliers provides both creative freedom and reliable results in jewelry fabrication.

Budget and cost of ownership

When choosing a 3D printer tailored for jewelry casting, balancing the initial cost against the features offered plays a significant role. Machines that provide high precision and fine detail tend to have a higher upfront price but are often worth the investment for professional results. The expenses for consumables such as resins or filaments and replacement parts like nozzles or build plates should also be factored into the overall costs, as these can impact long-term affordability.

The expenses for consumables such as resins or filaments and replacement parts like nozzles or build plates should also be factored into the overall costs, as these can impact long-term affordability. Considering the printer as a long-term investment is particularly important for those planning to use it regularly for professional purposes. Durable materials, reliable performance, and consistent print quality contribute to better value over time, reducing the need for frequent repairs or upgrades.

Understanding these elements helps in making a well-informed decision that aligns with both immediate needs and future demands in jewelry production.

FAQ’s

How Do Resin-Based Printers Compare To Filament-Based Printers For Jewelry Making?

Resin-based printers offer higher resolution and finer detail, making them ideal for intricate jewelry designs compared to filament-based printers. However, resin printers typically have higher operating costs and require more post-processing.

What Is The Price Range For Top-Quality Printers Used In Jewelry Casting?

Top-quality printers used in jewelry casting typically range from $5,000 to $20,000, depending on features like resolution and build size. High-end models with advanced capabilities can exceed this range for specialized applications.

Are There Specific Materials Compatible With Printers Ideal For Jewelry Casting?

Yes, certain resin materials specifically designed for 3D printing are ideal for jewelry casting, such as castable resins that burn out cleanly without residue. These materials ensure high detail and smooth surfaces, making them perfect for creating intricate jewelry molds.

What Features Should I Look For In The Best Printer For Jewelry Casting?

The best printer for jewelry casting should offer high resolution and precision to capture intricate details, along with reliable resin compatibility specifically designed for casting patterns. Additionally, a stable build platform and efficient support structures are essential for producing accurate and distortion-free models.

Which Printers Offer The Highest Resolution Suitable For Detailed Jewelry Designs?

Printers that offer the highest resolution suitable for detailed jewelry designs are typically resin-based 3D printers, such as SLA (Stereolithography) and DLP (Digital Light Processing) printers. Brands like Formlabs Form 3 and Anycubic Photon Mono X are popular choices due to their ability to produce ultra-fine details with layer resolutions as low as 25 microns.

Conclusion

Selecting the best 3d printer for jewelry casting depends on balancing precision, material compatibility, and ease of use. Models that offer high-resolution printing with specialized resins provide detailed results essential for intricate jewelry designs.

While some options may come with a steeper learning curve or higher upfront cost, they often deliver superior quality and reliability, crucial for professional or small-scale production. For those aiming to create detailed, accurate jewelry pieces, investing in a printer specifically designed for casting applications will likely result in fewer casting errors and less post-processing work. Ultimately, choosing a 3d printer tailored to jewelry casting needs can streamline your workflow and enhance final outcomes, making it a practical choice for hobbyists and professionals seeking quality and efficiency without unnecessary complexity.